AXN Clouds Fly

From ivc wiki

Jump to navigationJump to search

This is a powered remote controlled glider plane. It is balanced, forgiving in flight, has curved wingtips for stability, a powerful motor for steep climbs and ultra fast pass-bys, and characteristics to glide around forever on thermals.

Specifications

- Also called Floater Jet by Hobby King

- Released: 2008

- Type: Powered glider, high mount pusher

- Airframe: Dense and smooth EPO (Expanded polypropylene) foam [1] [2] [3]

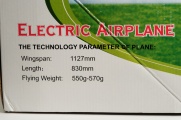

- Length: 840 mm (measured)

- Wingspan 1280 mm (measured)

- Wing area: 0.23 m^2 / 23dm^2

- Center of gravity: 51.5 mm, range 49-55 mm from LE

- Stock weight: 600-650 grams (Servo, ESC, Rx, Bat)

- Payload capacity: 200-350 grams (at least) [4]

- Reinforcement: Black 750x8 mm glass fiber spar tube in the wings and embedded tube along in the tail section

- Recommended flying area: 300x300 meters

- Product page: http://www.rc-model.cn/802.htm

Kits

- AXN-clouds AXN Floater-Jet with Servo, Motor, ESC, EPO (PNF) - Hobby King 53USD [5]

- AXN-C-MOT Floater-Jet EPO with Motor (ARF) - Hobby King March 2011 40USD

- AXN-C-KIT Floater-Jet EPO (ARF) - Hobby King March 2011 35USD

- AXN-802SET AXN Floater-Jet Set EPO with servo, motor, esc, battery (PNF) - Low Price RC 60USD

- AXN-802 AXN Floater-Jet EPO with motor (ARF) - Low Price RC 40USD

- Similar airplanes:

Manual

- Manual for AXN Clouds Fly

- Manual for BMI Arrow - Setup is essentially the same

- Manual for Align RCE-BL15X ESC - Programming is the same

Stock setup

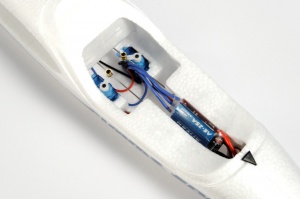

- Motor: AX-2208N 2150 KV Outrunner 27.7x31.4mm (DxW), 3mm shaft, 40 gram, 18A with 5x5 prop 3s, 9 mm tube motor mount, 16x16 mm bolt pattern [8]

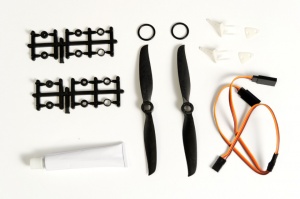

- Propeller: EMP 5x5 Electric propeller, comes in pairs

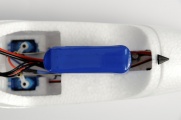

- ESC:

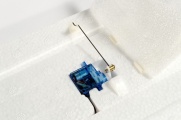

- Servos: Blue Micro Servo 9 grams JR-connector

My Setup

- AXN Clouds Fly Setup - My preferred way to set-up the plane and pre-flight procedure.

Tips

- Center of gravity 49-55 mm from leading wing edge, on wing spar rods, 56 mm minimum drag [12] [13] [14] [15] [16] [17]

- CG perfect with 3S 2200 mAh battery, a 1300 mAh too light, tail heavy, need to expand the room for the battery under canopy

- First flights, best to set up CG as far forward as possible and a little noise heavy then tail heavy [18]

- Change prop to 6x4E for more efficient flight, avoid going over 18A on stock motor and ESC combination [19]

- Replace stock 20A/25A ESC for a safer more capable 25A or 30A, using a higher rated ESC than necessary will run inefficient, less flight time although cool ESC, now comes with 25A ESC stock

- Get an ESC with +10A over the maximum amperage for the motor [20]

- Fasten the battery and canopy properly to allow rolls and loops without loosing parts

- Add fiber reinforced tape to the bottom of the plane to ease landing on rough surfaces

- On stock motor, re-glue magnets with epoxy or CA glue after a few flights

- Use a rubber-band and mounts, magnets, or velcro, to keep the wings tighter together [21] [22]

- Mount the propeller the right way, the concaved or inward bent curve of the propeller should face the tail, text the front

- The text must face toward the front, or on pusher propellers to the back [23]

- If propeller is mounted the correct way but rotates the wrong way, swap any two of the three motor wires between the motor and ESC

- Cut off excess length of the push-rods to avoid poking holes in battery or ESC

- During launch, use 45-50% throttle, trim elevator down a few clicks or program flap-switch to 15-20% elev up to avoid diving, hard throw 20% up into the air, clear elevator up trim [24] [25] [26] [27] [28]

- Use blue threadlock on push-rod connectors and any metal to metal screws or nuts

- Use threadlock on all screws on the motor and motor mount [29]

- Loosen up the foam on rudder, elevator, aileron hinges, or cut them off and re-attach with packing tape

- Use 3M double-sided tape to fasten and packing tape to cover the aileron servos, easy to remove for later repairs

- FPV: video transmitter on the tail, OSD in bottom of fuselage, camera on canopy, 1800 mAh battery forward

- Pick a small enough propeller to allow the motor to run efficiently, avoid overloading and burning the motor, use WebOCalc [30]

- Change the prop-saver for a collet-adapter, less vibration, prop-saver not needed on pusher plane [31]

- Straighten crooked foam by dipping it in hot 80-90 degrees C water for 1-5 minutes, reform it by hand and use a spoon for any pimples [32] [33]

- Mix 30-50% rudder into aileron on the transmitter for tighter corner turns [34]

- Set-up throttle-to-elevator mixing on Tx, -15% to stay flat on all throttle positions [35]

- Mark the wingtips with red decals/tape to easier identify the orientation of the airplane against the sky

- Always take-off against the wind and the same for landing, against the wind as lower landing-speed requires more lift to avoid stall

- Use the inner-most hole on the wing-horn and the outer-most hole on the servo-arm for maximum throw [36] [37]

- To make the plane less reactive/twitchy for beginners, use push-rod on inner hole of servo and outer hole on the control horn, can also be range/exponential limited on transmitter [38]

- Flaperons can help to make landing and launching easier, more angle of attack for resistance and decrease airspeed, replace Y-cable by two seperate aileron channels, programmed by the transmitter, spoilerons are flaperons inverted up [39]

- Thrust line should pass through both the center of mass and the center of drag [40] [41]

- Motor pod should have an angle pointing through the center-of-gravity point, called thrust line, to minimize elevator pitch down effect when throttling up the motor [42]

- For prop-saver, attach the o-ring around the prop and to the 2 grub screws straight no crossing, more centered this way [43] [44]

- Change the motor if the motor begins to vibrate during testing and propeller is balanced, motor is unbalanced [45]

- To keep the same ESC current draw, when going up in prop size go down in motor Kv [46]

- Throws: aileron 10 mm up or down, use outside hole of horn, elevator 5mm up or down, middle hole, rudder 20 mm both ways, middle hole [47] [48]

- For maximum aileron throw, adjust travel on transmitter to 140% and cut a dent in the EPO at the edge for the servo arm and push-rods [49]

- Turn the servos around with the head pointing to the rear, frees up servo arm movement and avoids binding on max down, easiest accomplished by swapping right with left servo

- Add a gyro to aileron for more stable flight in windy conditions, will give minimum roll effect on rudder input, use fast servos [50] [51]

- Use a gyro on elevator (pitch) to make landing easier in gusty wind conditions [52]

- On a 45 degree dive and 1/4 throttle, release elevator stick, plane should level back, tail heavy if continuous dive and nose heavy if alternating climb/diving bumping [53] [54]

- The thrust-to-weight ratio is 1:1 when a motor generates the same thrust as the weight of the plane [55]

- Minimum 1:2 static thrust to weight for leisurely flight, 1:1 for aerobatics, and atleast 1.4:1 for 3D and hovering [56]

- Wrap ferrite ring on BEC power lead to receiver to eliminate high frequency current noise from the ESC, 5-7 times round, helps wobbly lines on FPV cameras [57]

- Propeller dimensions, e.g. 6x4, means that the diameter (length) is 6-inches and the total distance traveled for one rotation is 4-inches [58]

- Increased prop-pitch gives increased speed but poorer acceleration, increased diameter increases thrust and current draw but lowers RPM and speed [59] [60]

- Flatten wing tips or shorten them for better rolls, speed and agility, it decreases the dihedral-effect [61] [62]

- Desolder cable between ESC and motor to add 3.5 mm bullet connectors with heat shrink, easier for repairs and to replace ESC

- Enable air-brake on ESC to stop propeller free-turning on no throttle and gliding, will draw small amount of current [63]

- Put the two Y-cable connectors in the square space between the wing halves [64]

- For a more stable elevator, make a groove on the underside and put a 3-4mm carbon fiber rod from tip to tip, use any type of CA glue, perhaps white tape on top [65] [66]

- Balance propeller using a magnetic bearing propeller balancer, add thin tape to the back of the lighter blade of the propeller or sand the back of the heavy side, not the tips [67]

- ESC setup: motor brake ON, battery type Lipo, battery low cut-off, cut-off voltage high (3.2V), start mode normal, timing mode high, govenor mode off [68]

ESC Setup

- Air break: On (Hold propeller still)

- Battery type: Lithium-ion Polymer (LiPo)

- Cut-off type: Soft-cut (Gracefully lower motor power)

- Cut-off voltage: High (3.1V)

- Start mode: Normal (Instant acceleration)

- Timing mode: High (12+ pole motors)

- Lipo cells: Auto detect

- Governor mode: Off (Heli only)

Swap 2 of the 3 motor wires to reverse the motor rotation to go clockwise seen from the tail.

Glues

- Polyurethane (PU) - Light, foams, some filler, humidity activated, slow curing, must be pressed during curing - Best for fixing any type of foam, deep cracks [69] [70]

- Gorilla Glue Quick Cure, Loctite SUMO (less foam)

- Cyanoacrylate (CA) - Flows into cracks, brittle - Fasten plastic parts together, e.g. servo horns, sizing ring propeller, carbon fiber rod to foam

- Super Glue, Krazy Glue

- Epoxy - Structural, filler - Any structure, undercarriage, FPV camera-mount

- Various curing time and brands available

- Contact adhesive - Flexible, sticky

- Silicone adhesive - Flexible - Mount plastic to foam, e.g. motor mount to foam [73]

- Loctite, Liquid Nails

- Hot glue - Heavy, could melt foam - Fasten plastic to foam, e.g. position servos or plastic motor mount

- Try thin, medium warm glue

Upgrades

This is a list of possible upgrades. Most of the parts should in theory fit and work with the Clouds Fly. To find the product, search for the listed name.

- Battery:

- Hyperion G3 VX 3S 2200 mAh 35C

- ZIPPY Flightmax 2200mAh 3S1P 20C

- Turnigy 1800mAh 3S 20C Lipo Pack [74]

- ESC:

- Turnigy Plush 30amp Speed Controller [75]

- Turnigy Plush 40amp Speed Controller [76]

- Turnigy Plush 25amp Speed Controller - gets hot

- Castle Creations Thunderbird 36 ESC

- TowerPro H40A Brushless Speed Controller [77]

- HobbyKing 40A BlueSeries Brushless Speed Controller [78]

- HobbyWing Pentium 25A Programmable Brushless ESC [79]

- Misc:

- Motor:

- Grayson GH Micro Jet V3 2200 KV Brushless Outrunner Motor - Light 34 grams, powerful [85] [86]

- Hoffman Magnetics Super Sport Series Outrunner 2470kv - Powerful, try 4.75x4.75 or 5x5 prop [87] [88]

- MicroDAN 2505 Speed 2800 Kv Bright Finish - Pricey, mounting tube 8 mm, new mounting plate needed, 6x4E Sport prop S3 [89] [90]

- Suppo 2212-06 2200KV motor [91] [92] [93]

- BP A2212-6 - Same as Suppo 2212-06

- Grayson GH Super Mega Jet V2 2550 KV Brushless Outrunner - Try apc 6x4e prop [94] [95]

- TowerPro 2409-12T Brushless Outrunner 1600Kv - Powerful, try, 6x4e, 7x6e prop, silent, mounting tube 9mm, direct drop-in, soft steel, use collet-adapter [96] [97] [98] [99] [100] [101] [102] [103]

- RCTimer BC2826-6 2200kv - Powerful, try TGS 6x4E/6x5E prop [104] [105] [106] [107] [108]

- RCTimer 2212-6 2200kv - Same as RCTimer BC2826-6 [109] [110]

- Emax CF2822 1200 KV Outrunner Brushless Motor - Mounting tube 10-11mm [111]

- Emax CF2812 1600 KV Outrunner Brushless Motor - Mounting tube 10-11mm [112]

- FC 28-12 Brushless Outrunner 1534kv - Clone of Emax CF2812, try 7x6, mounting tube 11mm [113] [114]

- A2208/9 17A 2200KV Outrunner Brushless motor V2 - Try 5x5 prop [115] [116]

- Moxie MOX-X2208N-2100 Brushless Outrunner Motor 2100KV - Try 5x5 prop, mounting tube 8mm, direct drop-in, very similar to stock motor [117] [118] [119]

- Scorpion SII-2212-1850KV V2 - Try 5x5E [120] [121] [122]

- Black Mantis B2836 2200kv Inrunner Brushless Motor - Silent [123]

- hexTronik HXM2730-3000 Brushless Outrunner 3000kv - Light 24 grams, try 4.1X4.1 prop, mounting tube drop-in, HK comment [124]

- Turnigy TR 28-26 16A 1900Kv Brushless Outrunner, HK comment [125] [126]

- Turnigy TR 35-30A 1700kv Brushless Outrunner - Try APC 7x5e prop [127]

- Misc:

- MicroDan GBx Motor Mount - For converting backplate motors to 8mm tube style motor mounts

- HXT 8mm Alloy Motor Mount 2.5g [128]

- Propeller:

- APC 6x4E [129] [130]

- TGS Sport 6x4E Precision propeller - Less noise, climbs steeper, flies easier [131] [132] [133] [134]

- APC 6x3E [135]

- Master Airscrew 6x3.5 prop [136] [137]

- TGS 6x5E - For 2S battery [138]

- APC 6x4 Sport [139]

- APC 7x5E prop - Adjust motor pod angle

- APC 7x6E style

- Master Airscrew 6x6 3-prop [140] [141]

- Misc:

- Servo:

- Receiver:

- AR6110E DSM2 Compatible Parkflyer 2.4Ghz Receiver [155]

- Transmitter:

- Spektrum DX7 DSM 7CH

- Turnigy 9X 9Ch Transmitter

- Hobby King 2.4Ghz 6Ch Tx & Rx V2

- Futaba 7C 72MHz or 2.4GHz [156]

- Futaba 9C

- Gyro:

- Camera:

- Misc:

- Spektrum trainer cable 1/8-inch mono jack - For PPM out, EzUHF later on

- Light weight horn set - Same horn as stock horns

- Ultra Thin Foam Glue 40ml

- Evotite CA460 Foam Safe Super Glue (Medium)

- Turnigy High Density R/C LED Flexible Strip-White - Mount inside the foam

- XT Lipo Monitor 3S

- Turnigy Pure-Silicone Wire 16AWG Black

- Turnigy Pure-Silicone Wire 16AWG Red

- Turnigy Pure-Silicone Wire 18AWG Black

- Turnigy Pure-Silicone Wire 18AWG Red

- Turnigy 4mm Heat Shrink Tube Red

- Turnigy 4mm Heat Shrink Tube Black

- 3.5mm 3 wire Bullet-connector - Between motor and ESC

- Nylon T-Connectors Deans - For ESC

- JR Y Servo Lead 30CM Length

- 15CM Servo Lead Extention (JR) 26AWG

- High stength fiber tape 20mm x 50mtr

- Nylon Snap-Click style clevis - For rudder and elevator pushrod

- Pushrod Snap Connectors 1.5mm - For servo arms

- Dubro Servo Arms Micro XL

- Gorilla glue amber - To fix foam [163] [164]

- HXT900-G HXT900 Replacement Gear Set

- Aileron horn low-profile 18x16x1mm - For holding wings together with rubber band

- Carbon Fiber Tube (hollow) 3x2x750mm - For elevator strength

- 5 Spoke Wheel Shock Absorbing D60xH18mm [165] [166]

- Turnigy Watt Meter and power Analyzer [167]

- Quality Epoxy Glue 30 minutes

- Double Sided Tape Pack 110BS - For aileron servos

Shops

- Hobby King / hobby city / United Hobbies - Great prices, large inventory

- Giant Cod - In UK, similar inventory to HK

- ThrottleStore - Spare parts for Clouds Fly

- Low Price RC - Propeller and motor selection

- Grayson Hobby - Quality motors and adapters

Guides

- venquessa, how to glide forever

- Webocalc motor and prop calculator

- DriveCalc

- MotorCalc

- Batch1/jtl gti, how to remove motor

- Spanish Clouds Fly build instruction video

- Carbon rod installation in foam

- mount motor using x-mount

- easy glider fpv project

- ajbaker, wheels on Floater Jet

- Clouds fly vs Arrow

- gc9n, GoPro mount

- gc9n, fpv, changing canopy

- smaerd58, video covering the basic setup

- Aircraft Center of Gravity Calc

Threads

- AXN Floater-Jet (aka Cloud Fly) - Huge thread

Terms

- LE - Leading-Edge of the wing

- WOT - Wide-open Throttle

- CG - Center of Gravity

- COG - Same as CG

- CL - Center of Lift

- AUW - All Up Weight

- TOW - Take-Off Weight

- LG - Landing-Gear

- EPO - Expanded PolyOlefin

- EPP - Expanded PolyPropylene

Builds

- hallstudio, Motor benchmark with 5x5 and 6x4 prop

- g00bd0g, AXN Floater Jet + GoPro HD FPV

- EasyStar, EasyGlder, Minimoa and AXN Floater Jet

- jbc, AXN Floater jet By HobbyKing

- nakelp86, ANX opened

- venquessa FPV build

- rodrigov, detatchable wingtips

- smaerd58, video of setup

- medvikek, esc under battery

- saucisse, fpv setup with ezosd

- yellowcolorado, 365 watt/32A with 40A esc [168]

- flatbus, rctimer 2212-6 motor mount

- pghern, rctimer 2208-12 motor mount

- gc9n, glassfiber reinforcement

- rightthere, complete CF fpv kit

- victapilot, water floats and inrunner

- icaq, hobby king tx and rx

- mookieman, install a x-mount motor

- tankd0g, cf-28-12 and bc-2212/6, 6x4 prop

- eyeinsky1, wheels, gopro hd, 1800 mAh, 6x4 prop, camera mount, slow speed stall fix [169]

- nyc863, great go pro hd video

- smaerd58, nimh batteries, 25a esc, turnigy tx and rx

- cholo, fpv setup, tilt&pivot, base station

- theothercliff, detailed airplane setup and flight tips

- nakelp86, fpv setup

- LittleG, orange paintjob

- beautox, build with Hoffmann 2470KV, TowerPro 40A ESC