MakerBot

The MakerBot is an open source 3D-printer. Great for experimenting with designs and small manufacturing. The latest model, Thing-O-Matic, has improved printing accuracy and expanded electronics platform.

I don't currently own a Makerbot.

Illustrations

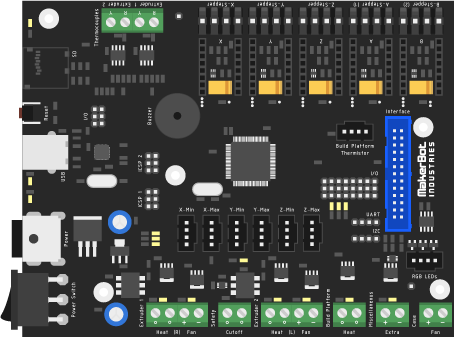

MakerBot Electronics

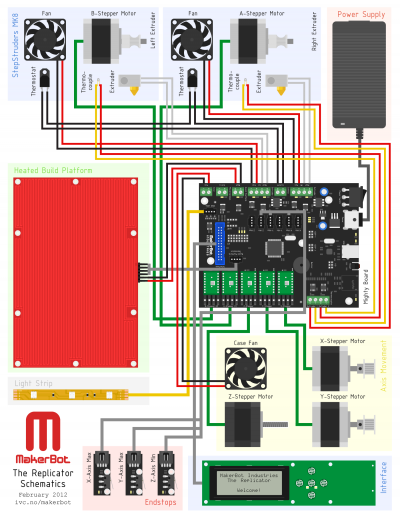

On the Thing-O-Matic all the electronics are neatly hidden away under the build platform, including the power-supply. On the new The Replicator all the separate boards are implemented in a new mainboard, called the Mighty Board.

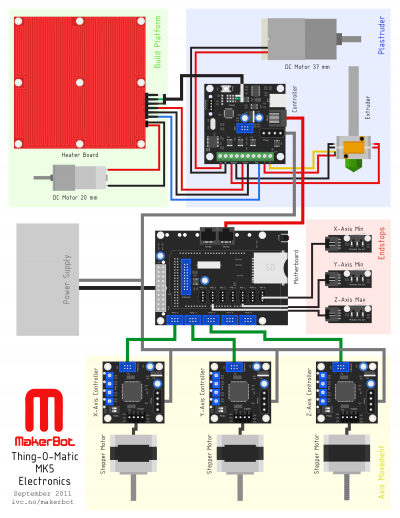

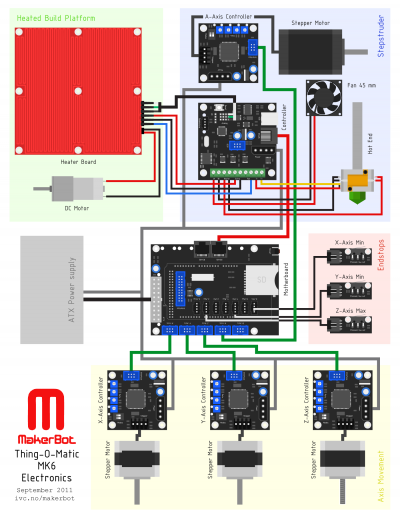

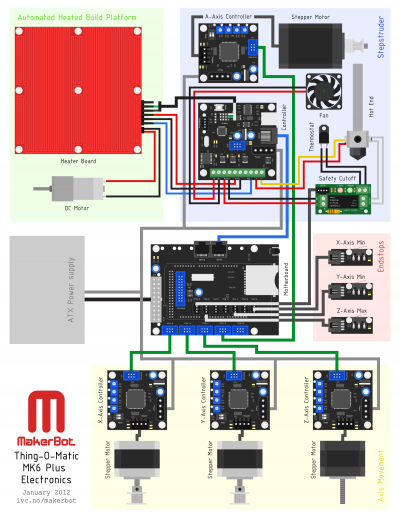

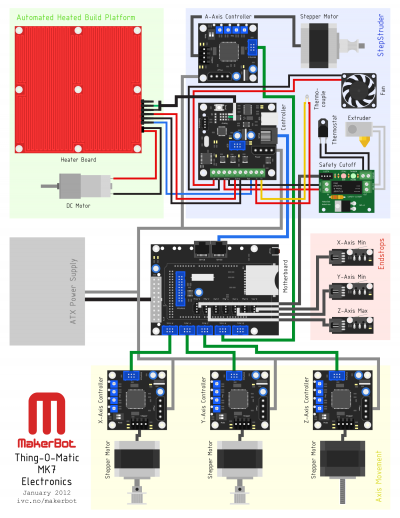

The electrical connections is shown in the overview image below. It shows all the components and how they're connected. For more details and photos of the assembly, check the official Thing-O-Matic electronics installation pages.

Illustrations:

- Download Thing-O-Matic MK5 electronics schematic - PDF vector version

- Download Thing-O-Matic MK6 electronics schematic - PDF vector version

- Download Thing-O-Matic MK6 Plus electronics schematic - PDF vector version

- Download Thing-O-Matic MK7 electronics schematic - PDF vector version

- Download The Replicator MK8 electronics schematic - PDF vector version

For PNG versions, check the images below. Hi-res versions are available when you click through to the final link.

MakerBot Thing-O-Matic MK5

- Download MakerBot Thing-O-Matic MK5 vector files - Boards and all components, Illustrator, PDF, PNG versions

MakerBot Thing-O-Matic MK6

- Download MakerBot Thing-O-Matic MK6 vector files - Boards and all new components (Illustrator, PDF, PNG versions)

MakerBot Thing-O-Matic MK6 Plus

- Download MakerBot Thing-O-Matic MK6 Plus vector files - Boards and all new components (Illustrator, PDF, PNG versions)

MakerBot Thing-O-Matic MK7

- Download MakerBot Thing-O-Matic MK7 vector files - Boards and all new components (Illustrator, PDF, PNG versions)

MakerBot The Replicator MK8

- Download MakerBot The Replicator MK8 vector files - Boards and all new components (Illustrator, PDF, PNG versions)

Symbols

All the components below has been compiled into a Frizing library to be used for prototyping, the connection-points has bin omitted. The original illustrator files are available in the section above.

Packages:

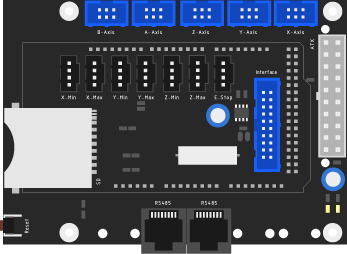

MakerBot Thing-O-Matic

Main board

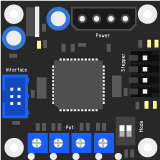

The main board is mounted together with a Arduino-controller. An external USB-interface allow commands to be sent via [1] ReplicatorG] and a SD-card slot can be used to load files to be printed in sequence locally. A row of connectors hooks up the stepper motor controllers, extruder controller, and endstops.

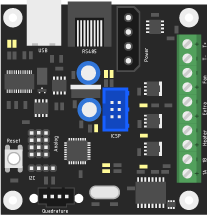

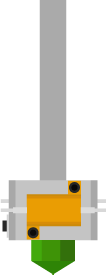

Extruder

This board has inputs from the thermalcouple temperature measuring probe, high-power MOSFET to drive current the main heater to melt plastic and heat the assembly board. Auxiliary connections for controlling the automated assembly plate and heat sensor for the board temperature control.

On top of the extruder is the feed for the plastic, driven by a DC-motor from the extruder controller. The heat element is a long piece of metal tube to keep the heat and melting process even. Two heat resistors exerts heat onto the main metal block before the plastic is extruded through a narrow nozzle. The thermocouple is mounted on the main block.

On the newer MK6 and MK6 Plus models the DC-motor is swapped in favor of a more precise stepper motor. The heater element is also upgraded to a custom made heater cartridge coupled with a safety cutoff board.

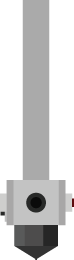

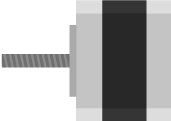

Stepper Controller

To drive the stepper motors, a controller can control the motion of the axis down to an accuracy of 1.8 degrees per step. The operation can be fine tuned using 4 potentiometers on the controller. Two dip-switches determine the type of stepper-motor that will be attached.

End stops

Each axis has an end-stop to signal when its at the farthest/closes point in its range.

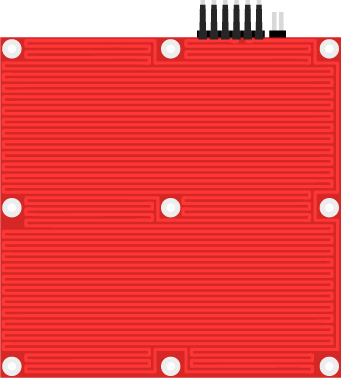

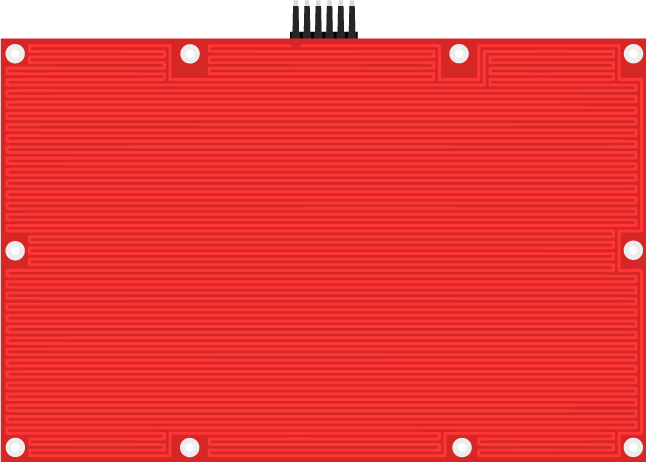

Heater board

To keep the plastic from shrinking during the printing process, the base where the object sits is heated by a copper maze on the board. A thermistor underneath is monitoring the temperature. On the automated model the base can roll out when the object is finished.

MakerBot The Replicator

Main board

The new main board is a implementation of the separate boards on the Thing-O-Matic. This will hopefully reduce the cost of the MakerBot.

Extruder

The same MK7 extruder is used on The Replicator, only in dual configuration. This allows for mid-run change of materials. Both support and colors can be changed. Colors can even be loaded during a print when the other is not in use.

End stops

To detect the end of travel, the same unchanged end stops are used.

Heater board

One of the main differences on The Replicator is the much larger build platform, almost twice the area. The construction is as before, only on wider and deeper.