Difference between revisions of "PCB Design"

| (74 intermediate revisions by the same user not shown) | |||

| Line 9: | Line 9: | ||

** [https://github.com/adafruit/Adafruit-Eagle-Library Adafruit Eagle Library] | ** [https://github.com/adafruit/Adafruit-Eagle-Library Adafruit Eagle Library] | ||

*** Ladyada has made a library for most of the parts used in their tutorials | *** Ladyada has made a library for most of the parts used in their tutorials | ||

* CAM, Computer Aided Manufacturing, to create processing files for | * Altium libraries: | ||

** [[Altium Designer]] | |||

== CAM == | |||

CAM, Computer Aided Manufacturing, to create processing files for fab houses. | |||

** [http://www.sparkfun.com/tutorial/BeginningEmbedded/9-EaglePCBs/sfe-gerb274x.cam SparkFun sfe-gerb274x.cam CAM] - Excellent generator of the necessary gerber and drill files, picks the right layers | ** [http://www.sparkfun.com/tutorial/BeginningEmbedded/9-EaglePCBs/sfe-gerb274x.cam SparkFun sfe-gerb274x.cam CAM] - Excellent generator of the necessary gerber and drill files, picks the right layers | ||

** Creates the proper gerber files for manufacturing: | ** Creates the proper gerber files for manufacturing (highlighted are common for double-sided, one-sided silkscreen): | ||

*** | *** '''GLT''' - Top copper layer, main traces | ||

*** | *** '''GTS''' - Top soldermask, where to put tin/gold plated pads and mask all other green/other color | ||

*** | *** '''GTO''' - Top silkscreen, all text, lines, illustrations can be painted on top of the soldermask | ||

*** | *** '''GBL''' - Bottom copper layer, same bottom | ||

*** | *** '''GBS''' - Bottom soldermask, same bottom | ||

*** | *** GBO - Bottom silkscreen, same bottom | ||

*** | *** GTP - Top solder paste stensil, only needed for SMD assembly of parts on the board | ||

*** | *** '''TXT''' - NC type drill coordinates, for vias and mounting holes | ||

Also, include a txt-file with specific fabrication instructions for the design. This helps to minimize confusion and wasted manufacturing time. | |||

== CAD Software == | |||

* Cadsoft Eagle PCB - Huge community support, loads of libraries, great for smaller boards, but feels a bit like the '80s | |||

* [[Altium Designer]] - Industry standard, flexible, like Photoshop for electronics designers, quite expensive | |||

* KiCad EDA - Open source multi-platform schematics and PCB layout software | |||

* Viewplot - View the files coming out of Eagle for verification | |||

== Good practices == | == Good practices == | ||

| Line 27: | Line 39: | ||

* '''Clearances:''' | * '''Clearances:''' | ||

** Width: 10 mils / 0.254 mm - spacing between traces | ** Width: 10 mils / 0.254 mm - spacing between traces, pads, vias. Also same signal smd components, pads, vias - ground pour isolation can be set in polygon properties | ||

* '''Distances:''' | * '''Distances:''' | ||

** Board edge isolation: 12-50 mils / 0.3048-1.27 mm - for clean routing cut or v-score and avoiding shortcircuitings | ** Board edge copper isolation: 12-50 mils / 0.3048-1.27 mm - for clean routing cut or v-score and avoiding shortcircuitings | ||

** Drill and hole distance: 8 mils - minimum distance between drill holes | ** Drill and hole distance: 8 mils - minimum distance between drill holes | ||

* '''Sizes:''' | * '''Sizes:''' | ||

** Signal trace width: 12-16 mils / 0.254-0.4064 mm - enough distance to avoid shortcircuiting of traces | ** Min. width: 8 mils | ||

** Power trace width: 16-24 mils / 0.4064-0.6096 mm - allow large currents to flow in vcc and ground traces | *** Board frame width: 8 mils - used for cutting and panelizing | ||

** | *** Signal trace width: 12-16 mils / 0.254-0.4064 mm - enough distance to avoid shortcircuiting of traces during fab | ||

*** Power trace width: 16-24 mils / 0.4064-0.6096 mm - allow large currents to flow in vcc and ground traces | |||

** Min. drill size: 20 mils / 0.508 mm - minimum via and hole size, restricted by fab, use larger for better via-connections | |||

* '''Restring for pads, vias:''' | * '''Restring for pads, vias:''' | ||

** Percentage of drill size: 25% - enough surface to add solder | ** Percentage of drill size: 25% - enough surface to add solder | ||

| Line 47: | Line 61: | ||

** Add silkscreen labels to all connections and interfacing points | ** Add silkscreen labels to all connections and interfacing points | ||

** Add a revision and date label | ** Add a revision and date label | ||

** Use vektor text, size 0. | ** Use vektor text, size 0.05 mils, and bold ratio 15% | ||

* '''Ground pour:''' | * '''Ground pour:''' | ||

** Add a final rectangular polygon plane over the entire design and click Ratsnest - this helps to avoid board warping, better ground and signal conditions | ** Add a final rectangular polygon plane over the entire design and click Ratsnest - this helps to avoid board warping, better ground and signal conditions | ||

** To only see the board without the pour, use Ripup on the polygon | ** To only see the board without the pour, use Ripup on the polygon | ||

For further details, check this great resource: | |||

* [http://www.mbedded.ninja/pcb-design mbedded PCB design] | |||

== Required detailing == | |||

For production boards and for ease of use and handling, consider including a few or all of the following points: | |||

* Client logo or brand name, if requested | |||

* Model number or product id | |||

* Board revision number | |||

* Date, YYYY-MM-DD of last revision edit | |||

* Your initials, e.g. DASM for David Smith | |||

* Designators facing down or to the right, or clustered separate in component arrangement form | |||

* Specific test points or vias without tenting | |||

* Labels of pin-outs for connectors, solder pads, pin headers or test points | |||

== Checklist == | |||

* Run Design Rule Check (DRC) to find obvious faults | |||

* Check that necessary input protection is added, if needed (PTC, TVS didoes, etc) | |||

* Reverse-polarity Schottky diode right after the power source | |||

* No power or current carrying traces under sensors (accelerometers, gyroscopes, compass, etc.) | |||

* Fidutials, minimum two in each opposite corner, 1.5mm exposed copper with 3.0mm solder mask perimeter | |||

* View the top and bottom copper pour for weak areas or too thin bridges | |||

* Balanced ground pours on each side of the board to avoid tension bending large boards | |||

* Via ground stitching around the board perimeter | |||

== BOM Optimization == | |||

Optimizing the BOM is important to reduce the cost and part diversity to an absolute minimum. For instance, can a 560 Ohm and 1k Ohm resistor be reduced to 2x 1k Ohm resistors. | |||

* Reduce resistors to common values, e.g. LED resistors to closes other value (1k, 2k, 10k, etc) | |||

* Multiple individual resistors can be reduced to single array part | |||

== Board config == | |||

* FR-4, FR-406, FR-408, FR-5, G10, CEM3, Rogers, ceramics - Flex/0.6/0.8/1.0/1.2/1.6/2.0mm - FR4 stands for Flame Retardant material made of woven glass reinforced epoxy resin | |||

** Standard: FR4 1.6 mm thickness | |||

* TG130, TG190, TG230 - Different temperature thresholds before the laminate begins to soften | |||

** Standard: TG130 | |||

* 2/4/6/8 layers - Multiple signal, ground, and power layers | |||

** Standard: 2 layers | |||

* 0.5oz/1oz/2oz/3oz/4oz/5oz/6oz copper - Thickness top surface for traces and ground pour | |||

** Standard: 1oz | |||

* V-scoring / Tab-routing - Ways to separate boards from panels | |||

** Standard: Both - V-scoring for square designs, tab for all other | |||

* Surface finish - type of material added to exposed copper pads [http://www.multicircuits.com/pcb/tech/surface_finishes.html] [http://www.epectec.com/articles/pcb-surface-finish-advantages-and-disadvantages.html] | |||

** Standard: HASL / Immersion Silver | |||

** HASL (Hot Air Solder Leveling) - 63/37 tin, standard, cheap, stress issues, uneven surface | |||

** HASL Lead-free - not for fine pitch devices, RoHS compliant | |||

** Immersion Tin - historically popular, flat surface 20-40 micron, 3-6 months shelf life | |||

** ENIG (Electroless Nickel/Immersion Gold) - best for fine pitch devices, lead-free, 75 micron + 3-5 micron, excellent shelf-life | |||

** Immersion Silver - lead-free, 5-12 micron, 12 months shelf-life, cost effective | |||

** Hard Gold - expensive, long shelf-life, hard to solder to | |||

== Examples == | |||

These are some of the boards I've designed and got fabricated. | |||

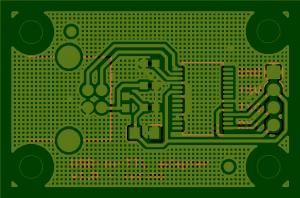

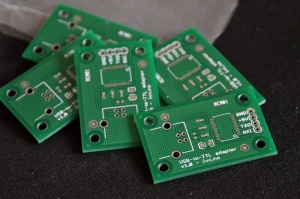

=== USB-to-TTL adapter === | |||

A small board I did for exploring Eagle | |||

[[Image:pcb_design_usb-ttl.png|300px]] [[Image:pcb_design_usb-ttl-photo.jpg|300px]] | |||

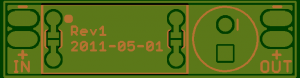

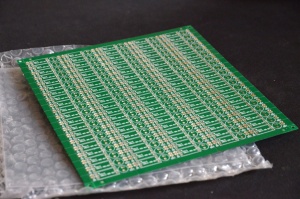

=== LC power filter === | |||

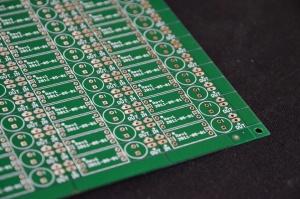

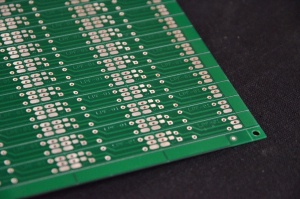

A compact and thin board ([http://ivc.no/lc_power_filter/ low-pass filter]) panelized for easy PCB assembly. | |||

[[Image:pcb_design_lpf.png|300px]] [[Image:pcb_design_lpf-photo.jpg|300px]] [[Image:pcb_design_lpf-photo-close-front.jpg|300px]] [[Image:pcb_design_lpf-photo-close-back.jpg|300px]] | |||

== PCB Manufacturers == | == PCB Manufacturers == | ||

To find a suitable manufacturer for your board can be daunting, but fortunately there is now a service which compares PCB manufacturers against a set of your parameters: | |||

* [http://pcbshopper.com/ pcbshopper.com] | |||

Another great place to start is Ladyada's [http://www.ladyada.net/library/pcb/costcalc.html PCB cost calculator]. It lets you compare different manufacturers by cost per square inch. Note: Prices from 2007. | |||

* [http://www.batchpcb.com BatchPCB] - Easy and cheap for small boards | * [http://www.batchpcb.com BatchPCB] - Easy and cheap for small boards | ||

=== BatchPCB order === | === BatchPCB order === | ||

In mid-December 2010 I tried BatchPCB, a SparkFun service | In mid-December 2010 I tried BatchPCB, a SparkFun service. Tried a sample board i designed. The result was satisfactory. I ordered 3 pieces but got 6 back, bonus! BatchPCB are putting multiple designs on a panel and shipping them to them to GoldPhoenixPCB. A small board including shipping is 15 USD, but the delivery time is 3 weeks. | ||

'''Timeline:''' | '''Timeline:''' | ||

| Line 68: | Line 152: | ||

This was during the xmas holidays and shipped from US to Norway, a normal turnaround would probably be 3 weeks. | This was during the xmas holidays and shipped from US to Norway, a normal turnaround would probably be 3 weeks. | ||

== | === GoldPhoenixPCB === | ||

* | Great for entire full panel runs with only a single board design, repeated. BatchPCB are using them. Based in Wuhan, China. Fast under 6 hour email response. Offers RoHS boards. | ||

** | |||

Small 36.4 L x 9.4 W x 0.8 H mm board, 200 pieces, one panel, order total 200USD inc. shipping. | |||

'''First batch timeline:''' | |||

* 2011-05-01 Design start | |||

* 2011-05-06 Submitted and processed | |||

* 2011-05-16 Final testing | |||

* 2011-06-17 Shipped Fedex | |||

* 2011-06-25 Arrived | |||

Round-trip for a batch is around 3 weeks. | |||

'''Second batch timeline:''' | |||

* 2012-01-14 New run request sent | |||

* 2012-01-19 Processed | |||

* 2012-02-02 Tested and shipped Fedex | |||

* 2012-02-07 Arrived | |||

Round-trip for a batch is little over 3 weeks. | |||

=== PCBCart === | |||

Haven't tried them yet. [http://www.eevblog.com/ Eevblog] are using them for [http://www.alternatezone.com/electronics/ucurrent/ uCurrent] and [http://www.eevblog.com/2010/11/29/eevblog-130-the-ucalc-credit-card-scientific-calculator-computer/ uCalc]. | |||

=== Futurlec === | |||

Possible to order single or double sided boards, with or without soldermask or silkscreen. US based. Simple [http://www.futurlec.com/PCBService.shtml quotation form]. A small board without silk or soldermask is 25 USD + shipping. | |||

=== PCBTrain === | |||

UK based. | |||

=== PCBPool === | |||

UK based. | |||

=== DorkBotPDX === | |||

Batch run of boards, sent off when the [http://www.dorkbotpdx.org/wiki/pcb_order board is full]. | |||

=== EzPCB === | |||

Low prices and value [http://www.rcgroups.com/forums/showthread.php?t=667068], offer prototyping and production services. | |||

=== EuroCircuits === | |||

Based on Begium, good prices, proper web order system, fast delivery options. [http://www.electronics-lab.com/blog/?p=20515] | |||

=== SeeedStudio === | |||

Chinese webstore offering PCB and laser cutting service, small 10pcs 5x5cm boards for 10USD, great for prototypes [https://www.element14.com/community/thread/5197]. Quality of the received batch was great, no obvious issues, a small serial number was added to the boards by the manufacturer which is not that nice. | |||

Small 28.5 L x 9.8 W x 0.8 H mm board, 11 pieces, order total 14.50USD inc. Airmail shipping. | |||

'''Timeline:''' | |||

* 2013-03-08 Submitted via web interface | |||

* 2013-03-15 Shipped | |||

* 2013-03-18 Traceable | |||

* 2013-03-26 Delivered | |||

Round-trip for this prototype batch was 18 days, pretty good. Faster shipping options are available so the shipping time can be cut down to 3-4 days. | |||

'''Timeline Express shipping:''' | |||

* 2013-09-02 Order placed | |||

* 2013-09-06 Shipped | |||

* 2013-09-08 Traceable | |||

* 2013-09-11 Delivered | |||

A turn-around time of 9 days using DHL express shipping, which is quite usable. | |||

=== OSH Park / DorkBotPDX === | |||

* Great for prototype runs or small quantity. US based, same system as BatchPCB. Ships a full panel when it has filled up. Around 2USD for a small board, you get 3 pcs, 5USD international shipping. | |||

=== DirtyPCBs === | |||

Very similar model to Seeed Studio where you pick a standard dimension set and quantity. Quality seems good going from [http://www.jechavarria.com/2014/07/29/prototyping-board-use-ip55-box/ these photos]. Free shipping! | |||

* [http://dirtypcbs.com/ dirtypcbs.com] | |||

=== JLCPCB === | |||

The most affortable PCB manufacturrer with great quality, as of 2019. For 2USD you get 10 pcs + shipping. | |||

* [https://jlcpcb.com/ jlcpcb.com] | |||

You can also combine JLCPCB with [https://lcsc.com LCSC] for full assembly of PCBs. | |||

== Smart Prototyping == | |||

Also offering a PCB service with several parametric, much like Seeed Studio. Can select whether to include a stencil, very handy. | |||

* [http://smart-prototyping.com smart-prototyping.com] | |||

== PCB Stencil == | |||

To make SMD/SMT assembly easier and faster, get a PCB stencil to put solder paste directly on all the exposed solder pads. For more details, see [http://learn.adafruit.com/smt-manufacturing/laser-cut-stencils Adafruit's SMT manufacturing guide]. | |||

Make sure to edit the top (or/and bottom) paste mask to remove any pads which should not have solder applied, e.g. jumper solder bridges, solder pads for wires, exposed areas, etc. In Altium, after exporting the Gerber files, it opens the Camtastic editor, used the Edit->Clear function to mark and right-click to delete, then Export->Gerber files to get the updated files. | |||

=== Seeed Studio === | |||

Starting at 70USD you can get a 37x47cm laser cut stainless-steel stencil for full production runs/fabrication houses. | |||

* [http://www.seeedstudio.com/service/index.php?r=st/stencil Seeed Studio Fusion PCB stencil] | |||

=== Ohararp Stencil === | |||

For small runs, Kapton stencil is cheap and works great for simple boards. Prepare the board outline (GKO) and top paste mask (GTP) gerber files and submit them using the easy ordering system. For 25USD+8USD shipping you can get a fairly large sheet, 215.9x279.4x0.0889mm (8.5″x11″x.0035″) - about the size of an A4 sheet. | |||

* [http://ohararp.com/stencils/ Ohararp Stencil service] | |||

=== OSH Stencil === | |||

Another good source. 0.30USD per square inch and low shipping cost. | |||

* [http://www.oshstencils.com/pricing.php OSH Stencils] | |||

== PCB Penalization == | |||

Putting multiple board designs on a single PCB panel can save wasted material and speed for the assembler. | |||

* [http://www.ami.ac.uk/courses/topics/0254_padep/ Panels and de-panelling tips] | |||

== PCB Assembler == | |||

=== Gold Phoenix PCB === | |||

Professional PCB assembler, can manufacture the PCBs and part assembly. | |||

* [http://goldphoenixpcb.com/ holdphoenixpcb.com] | |||

=== Smart Prototyping === | |||

Great for small runs. Fast response via email and focus on getting it right. Can do part sourcing. | |||

* [http://smart-prototyping.com smart-prototyping.com] | |||

* | |||

Latest revision as of 16:55, 29 October 2019

The the prototyping is done, putting the design proper PCB board makes it more rigid and possible to offer unassembled kits. The process is mostly straight forward but the design process to lay out the board requires some time to get right.

Eagle will be used here, it's cross platform and great part libraries.

Setup

- Eagle parts libraries:

- SparkFun Eagle Library

- Includes most of the parts SparkFun offer ont their website

- Adafruit Eagle Library

- Ladyada has made a library for most of the parts used in their tutorials

- SparkFun Eagle Library

- Altium libraries:

CAM

CAM, Computer Aided Manufacturing, to create processing files for fab houses.

- SparkFun sfe-gerb274x.cam CAM - Excellent generator of the necessary gerber and drill files, picks the right layers

- Creates the proper gerber files for manufacturing (highlighted are common for double-sided, one-sided silkscreen):

- GLT - Top copper layer, main traces

- GTS - Top soldermask, where to put tin/gold plated pads and mask all other green/other color

- GTO - Top silkscreen, all text, lines, illustrations can be painted on top of the soldermask

- GBL - Bottom copper layer, same bottom

- GBS - Bottom soldermask, same bottom

- GBO - Bottom silkscreen, same bottom

- GTP - Top solder paste stensil, only needed for SMD assembly of parts on the board

- TXT - NC type drill coordinates, for vias and mounting holes

Also, include a txt-file with specific fabrication instructions for the design. This helps to minimize confusion and wasted manufacturing time.

CAD Software

- Cadsoft Eagle PCB - Huge community support, loads of libraries, great for smaller boards, but feels a bit like the '80s

- Altium Designer - Industry standard, flexible, like Photoshop for electronics designers, quite expensive

- KiCad EDA - Open source multi-platform schematics and PCB layout software

- Viewplot - View the files coming out of Eagle for verification

Good practices

Some of these guidelines can be used in the Design Rules property window in Eagle. The PCB manufacturer normally provide a list of minimum requirements for their equipment/method.

Design rules:

- Clearances:

- Width: 10 mils / 0.254 mm - spacing between traces, pads, vias. Also same signal smd components, pads, vias - ground pour isolation can be set in polygon properties

- Distances:

- Board edge copper isolation: 12-50 mils / 0.3048-1.27 mm - for clean routing cut or v-score and avoiding shortcircuitings

- Drill and hole distance: 8 mils - minimum distance between drill holes

- Sizes:

- Min. width: 8 mils

- Board frame width: 8 mils - used for cutting and panelizing

- Signal trace width: 12-16 mils / 0.254-0.4064 mm - enough distance to avoid shortcircuiting of traces during fab

- Power trace width: 16-24 mils / 0.4064-0.6096 mm - allow large currents to flow in vcc and ground traces

- Min. drill size: 20 mils / 0.508 mm - minimum via and hole size, restricted by fab, use larger for better via-connections

- Min. width: 8 mils

- Restring for pads, vias:

- Percentage of drill size: 25% - enough surface to add solder

- Min. width: 12mils - minimum restring size

- Max. width: 20mils - maximum restring size

- Masks:

- Stop soldermask: 4 mils / 100% / 4 mils - Bleed a litt over the pad or via to make sure it's properly tinned

- Soldermask limit: 32 mils - little higher than the largest via to cover them with the mask instead of open tin/gold plating, aka. tented

Other:

- Labels and text:

- Add silkscreen labels to all connections and interfacing points

- Add a revision and date label

- Use vektor text, size 0.05 mils, and bold ratio 15%

- Ground pour:

- Add a final rectangular polygon plane over the entire design and click Ratsnest - this helps to avoid board warping, better ground and signal conditions

- To only see the board without the pour, use Ripup on the polygon

For further details, check this great resource:

Required detailing

For production boards and for ease of use and handling, consider including a few or all of the following points:

- Client logo or brand name, if requested

- Model number or product id

- Board revision number

- Date, YYYY-MM-DD of last revision edit

- Your initials, e.g. DASM for David Smith

- Designators facing down or to the right, or clustered separate in component arrangement form

- Specific test points or vias without tenting

- Labels of pin-outs for connectors, solder pads, pin headers or test points

Checklist

- Run Design Rule Check (DRC) to find obvious faults

- Check that necessary input protection is added, if needed (PTC, TVS didoes, etc)

- Reverse-polarity Schottky diode right after the power source

- No power or current carrying traces under sensors (accelerometers, gyroscopes, compass, etc.)

- Fidutials, minimum two in each opposite corner, 1.5mm exposed copper with 3.0mm solder mask perimeter

- View the top and bottom copper pour for weak areas or too thin bridges

- Balanced ground pours on each side of the board to avoid tension bending large boards

- Via ground stitching around the board perimeter

BOM Optimization

Optimizing the BOM is important to reduce the cost and part diversity to an absolute minimum. For instance, can a 560 Ohm and 1k Ohm resistor be reduced to 2x 1k Ohm resistors.

- Reduce resistors to common values, e.g. LED resistors to closes other value (1k, 2k, 10k, etc)

- Multiple individual resistors can be reduced to single array part

Board config

- FR-4, FR-406, FR-408, FR-5, G10, CEM3, Rogers, ceramics - Flex/0.6/0.8/1.0/1.2/1.6/2.0mm - FR4 stands for Flame Retardant material made of woven glass reinforced epoxy resin

- Standard: FR4 1.6 mm thickness

- TG130, TG190, TG230 - Different temperature thresholds before the laminate begins to soften

- Standard: TG130

- 2/4/6/8 layers - Multiple signal, ground, and power layers

- Standard: 2 layers

- 0.5oz/1oz/2oz/3oz/4oz/5oz/6oz copper - Thickness top surface for traces and ground pour

- Standard: 1oz

- V-scoring / Tab-routing - Ways to separate boards from panels

- Standard: Both - V-scoring for square designs, tab for all other

- Surface finish - type of material added to exposed copper pads [1] [2]

- Standard: HASL / Immersion Silver

- HASL (Hot Air Solder Leveling) - 63/37 tin, standard, cheap, stress issues, uneven surface

- HASL Lead-free - not for fine pitch devices, RoHS compliant

- Immersion Tin - historically popular, flat surface 20-40 micron, 3-6 months shelf life

- ENIG (Electroless Nickel/Immersion Gold) - best for fine pitch devices, lead-free, 75 micron + 3-5 micron, excellent shelf-life

- Immersion Silver - lead-free, 5-12 micron, 12 months shelf-life, cost effective

- Hard Gold - expensive, long shelf-life, hard to solder to

Examples

These are some of the boards I've designed and got fabricated.

USB-to-TTL adapter

A small board I did for exploring Eagle

LC power filter

A compact and thin board (low-pass filter) panelized for easy PCB assembly.

PCB Manufacturers

To find a suitable manufacturer for your board can be daunting, but fortunately there is now a service which compares PCB manufacturers against a set of your parameters:

Another great place to start is Ladyada's PCB cost calculator. It lets you compare different manufacturers by cost per square inch. Note: Prices from 2007.

- BatchPCB - Easy and cheap for small boards

BatchPCB order

In mid-December 2010 I tried BatchPCB, a SparkFun service. Tried a sample board i designed. The result was satisfactory. I ordered 3 pieces but got 6 back, bonus! BatchPCB are putting multiple designs on a panel and shipping them to them to GoldPhoenixPCB. A small board including shipping is 15 USD, but the delivery time is 3 weeks.

Timeline:

- 2010-12-16 07:43:39 Submitted, passed, paid and pending

- 2010-12-17 07:12:18 Processing

- 2011-01-03 10:39:40 Shipped

- 2011-01-13 14:39:00 Arrived

This was during the xmas holidays and shipped from US to Norway, a normal turnaround would probably be 3 weeks.

GoldPhoenixPCB

Great for entire full panel runs with only a single board design, repeated. BatchPCB are using them. Based in Wuhan, China. Fast under 6 hour email response. Offers RoHS boards.

Small 36.4 L x 9.4 W x 0.8 H mm board, 200 pieces, one panel, order total 200USD inc. shipping.

First batch timeline:

- 2011-05-01 Design start

- 2011-05-06 Submitted and processed

- 2011-05-16 Final testing

- 2011-06-17 Shipped Fedex

- 2011-06-25 Arrived

Round-trip for a batch is around 3 weeks.

Second batch timeline:

- 2012-01-14 New run request sent

- 2012-01-19 Processed

- 2012-02-02 Tested and shipped Fedex

- 2012-02-07 Arrived

Round-trip for a batch is little over 3 weeks.

PCBCart

Haven't tried them yet. Eevblog are using them for uCurrent and uCalc.

Futurlec

Possible to order single or double sided boards, with or without soldermask or silkscreen. US based. Simple quotation form. A small board without silk or soldermask is 25 USD + shipping.

PCBTrain

UK based.

PCBPool

UK based.

DorkBotPDX

Batch run of boards, sent off when the board is full.

EzPCB

Low prices and value [3], offer prototyping and production services.

EuroCircuits

Based on Begium, good prices, proper web order system, fast delivery options. [4]

SeeedStudio

Chinese webstore offering PCB and laser cutting service, small 10pcs 5x5cm boards for 10USD, great for prototypes [5]. Quality of the received batch was great, no obvious issues, a small serial number was added to the boards by the manufacturer which is not that nice.

Small 28.5 L x 9.8 W x 0.8 H mm board, 11 pieces, order total 14.50USD inc. Airmail shipping.

Timeline:

- 2013-03-08 Submitted via web interface

- 2013-03-15 Shipped

- 2013-03-18 Traceable

- 2013-03-26 Delivered

Round-trip for this prototype batch was 18 days, pretty good. Faster shipping options are available so the shipping time can be cut down to 3-4 days.

Timeline Express shipping:

- 2013-09-02 Order placed

- 2013-09-06 Shipped

- 2013-09-08 Traceable

- 2013-09-11 Delivered

A turn-around time of 9 days using DHL express shipping, which is quite usable.

OSH Park / DorkBotPDX

- Great for prototype runs or small quantity. US based, same system as BatchPCB. Ships a full panel when it has filled up. Around 2USD for a small board, you get 3 pcs, 5USD international shipping.

DirtyPCBs

Very similar model to Seeed Studio where you pick a standard dimension set and quantity. Quality seems good going from these photos. Free shipping!

JLCPCB

The most affortable PCB manufacturrer with great quality, as of 2019. For 2USD you get 10 pcs + shipping.

You can also combine JLCPCB with LCSC for full assembly of PCBs.

Smart Prototyping

Also offering a PCB service with several parametric, much like Seeed Studio. Can select whether to include a stencil, very handy.

PCB Stencil

To make SMD/SMT assembly easier and faster, get a PCB stencil to put solder paste directly on all the exposed solder pads. For more details, see Adafruit's SMT manufacturing guide.

Make sure to edit the top (or/and bottom) paste mask to remove any pads which should not have solder applied, e.g. jumper solder bridges, solder pads for wires, exposed areas, etc. In Altium, after exporting the Gerber files, it opens the Camtastic editor, used the Edit->Clear function to mark and right-click to delete, then Export->Gerber files to get the updated files.

Seeed Studio

Starting at 70USD you can get a 37x47cm laser cut stainless-steel stencil for full production runs/fabrication houses.

Ohararp Stencil

For small runs, Kapton stencil is cheap and works great for simple boards. Prepare the board outline (GKO) and top paste mask (GTP) gerber files and submit them using the easy ordering system. For 25USD+8USD shipping you can get a fairly large sheet, 215.9x279.4x0.0889mm (8.5″x11″x.0035″) - about the size of an A4 sheet.

OSH Stencil

Another good source. 0.30USD per square inch and low shipping cost.

PCB Penalization

Putting multiple board designs on a single PCB panel can save wasted material and speed for the assembler.

PCB Assembler

Gold Phoenix PCB

Professional PCB assembler, can manufacture the PCBs and part assembly.

Smart Prototyping

Great for small runs. Fast response via email and focus on getting it right. Can do part sourcing.