Solar Panel Charging

Basics about solar panel battery charging.

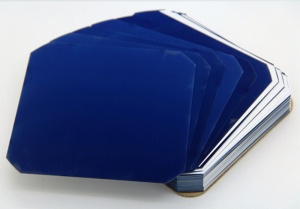

Panels

Monocrystalline panels are regarded as being the most efficient panel technology. Second to Polycrystalline panels. In, 2016, Sunpower is considered to have the best solar cell technology, they are also used on the Solar Impulse aeroplane.

Common configurations of individual panels:

- 100W - common

- 120W

- 150W - common

- 160W

- 300W

Arrays are usually build by parallel installation of multiple of the same panel type, e.g. 10x150W panels is a 1500W or 1.5kW array.

Some cheap flexible panels:

- 100W 18V Mono panel - 137USD

Solar controllers

There are two kinds of controllers; MPPT and PWM charging mode, with the former being the preferred one on larger (>50W) setups.

A reasonable decent solar controller starts at 50USD, for a 10 to 30A 12V setup. A 30A controller can handle up to 30 x 12 = 360W of solar panels connected to the input.

- Solar controller 30A 12V - 44USD

Batteries

Using regular 12V or 24V batteries makes it simple to get locally.

Building solar panels

It is possible to build a large solar panel from scratch. You only need to get the individual parts, which is really not that much or hard to put together.

- Solar Cell - photovoltaic module, converts sunlight to electric current, provides approx. 0.5V each

- Typical cells: 6x6-inches at 4.8W, 5x5-inches at 3.2W

- Solar Tabbing Wire - connects modules into strings - multiple cells connected together, e.g. 9 cells provides 4.5V (0.5V x 9)

- Bus Wire - forms an "S"-shape and connects the strings into an panel, e.g. 4 strings provides 18V (4.5V x 4)

- Flux Pen - makes it easier to solder the tabbing and bus wire

- Encapsulation Film - seals the front and back of the solar cells in a vacuum

- Backing Sheet - works as an insulator and protects the back of the panel, usually a multilayer laminate

- Mounting Frame - makes it easier to mount the panel to a roof or other installation infrastructure

- Junction Box - connects the two bus ends to screw terminals

- Cable - makes it easier to weatherproof and connect multiple panels together, e.g. in series (higher voltage) or parallel (more current)

- Diode - when panels are installed in parallel and one is damaged, a bypass diode allows the other panels to still work, also blocks reverse current flow, installed in the junction box