AXN Clouds Fly Setup: Difference between revisions

| Line 104: | Line 104: | ||

* AOXAN AE-25A Programmable ESC | * AOXAN AE-25A Programmable ESC | ||

* On-board BEC 5V 2A supply | * On-board BEC 5V 2A supply (two 1A FET transistors in parallel) | ||

* [http://beta.ivc.no/rc_airplane/general_esc_manual.pdf User manual] | * [http://beta.ivc.no/rc_airplane/general_esc_manual.pdf User manual] | ||

Revision as of 09:05, 6 March 2011

My preferred setup of the AXN Floater Jet.

Vertical Stabilizer

Glue the stabilizer in place using the supplied adhesive glue. Make sure it's in line with the canopy hook in front when looking from the back.

Flex the rudder back and forth to loosen up the foam hinge. The less force needed to move the rudder the less stress is put on the servo during flight. Alternatively cut them off and use clear packing tape to re-attach them, one slice on each side.

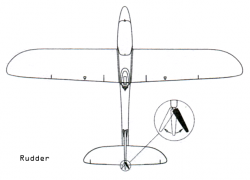

Rudder

- Push-rod: 1 mm

When using the stock horn set and push-rod, attach the horn set to the rod before clipping the horn to the rudder. The other way around will very difficult as the insertion angles will conflict.

A better method is to add a snap-style clevis between the horn and push-rod. This way it's possible to repair and disassemble the rudder and elevator easily. The stock Z-bend has to be straighten to a L-angled shape to work.

For maximum throw, use the lowest inner-most hole on the rudder horn and the outer-most on the servo arm. The stock servo arm already has a larger hole for the push-rod connector located close to the end. When replacing the servos make sure to pick the arm with the greatest throw and most number of holes.

Tail Pitch

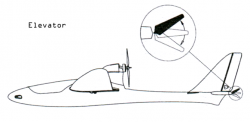

To make the plane as transportable as possible, the elevator is kept detachable. A rubber band around the front of the stabilizer is holding the elevator in place.

During fast dives the elevator could deflect, by making a groove and gluing a 3 mm carbon fiber rod from tip-to-tip would increase the strength.

Flex the elevator hinge to loosen up the foam.

Elevator

- Push-rod: 1 mm

For easy repair and disassemble, the same snap-style clevis as mentioned on the rudder should be installed.

Wings

The main wings comes with servos pre-installed and one glass fiber tube cover glued in place. To make it easier to remove and replace the servos I cut away a 2 mm thin foam slit along the length of the tube cover. The servo cable can then passed and tucked down into the canal.

Glue the other cover in place using the supplied adhesive glue. Sand down each end of the glass fiber tube slightly to make the insertion go smoother. I like to only insert the tube in the wings without any additional glue. This makes it easy to transport the plane and replace the tube if it should break.

To keep the wings together during flight, add two hooks to the underside of the wings and use a thick rubber band to force the wings against each other. Another possible method is to fit reasonably strong magnets or velcro.

Aileron

- Push-rod: 1 mm

For maximum throw, the aileron wing servos has to be swapped around vertically. The servo head should be pointing toward the back instead of the leading wing edge. The easiest way is to swap the left wing servo with the right, that way the adhesive double-sided pad stays on the same side (bottom).

Connect the servos to the receiver and power on the transmitter to center the servo arm. If the transmitter can be programmed, configure the throw, also called travel adjust, to 140%. Try moving the aileron stick and make sure the servo arm does not hit either side, any binding will quickly wear out the servos.

Battery

- Hyperion 3S 2100 mAH 25C 34x107x23mm 166grams Lipo

- Hyperion 3S 1300 mAH 25C 35x71x23mm 103grams Lipo

- Moxie 3S 2200 mAh 30C 36x102x26mm 198grams Lipo

- Moxie S3 1800 mAh 40C 35x103x21mm 164grams Lipo

To make a 2200 mAh Lithium-ion Polymer battery fit under the canopy and balance correctly, remove 3 mm foam on each side (6 mm total) of the centre canal using a hobby knife. It should be possible to move the battery all the way forward in the nose section.

I changed all the connectors to Deans T-type. The firm connection and great contact surface makes it ideal for high current applications.

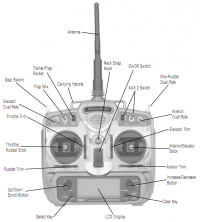

Transmitter

- Spektrum DX7

- User manual

This transmitter has 7 channels is programmable for both airplanes and helicopters. It has a 3-way flap switch, aileron and elevator dual rate switches, rudder mix switch, gear and aux2 switch. A preset memory makes it possible to set up several different models on the same radio.

Settings (other than defaults):

- Travel Adjust: THRO Low 102% - To make the motor stop on low thottle

- Aileron-to-Rudder mix: Rate 40% - Faster rolls

Receiver

- HobbyKing DSM2 Compatible 2.4 GHz receiver

- 6 Channels

- User manual

This is an excellent 6 channel tiny 4 grams receiver with signal path diversity. It comes bare but the case can be downloaded and printed. Add some foil to the inside panel of the case to make it even more immune to RF-noise.

Negative lead is the top pin, as opposed to the Spektrum receiver which is reversed. This means the brown or black wire of the 3 wires must face up. Accidently reversing the connector does not harm the receiver as the 5V power is the middle pin and won't short the circuit.

Mount the receiver in a location where the antennas can be 90 degrees perpendicular to each other, e.g. the vertical surface in cockpit over the elevator and rudder servos or in the bottom space of the fuselage.

Hook-up for 4 channels: (Looking from the top, pins to the right, from the bottom)

- BAT/Bind - Only used for binding

- THRO - ESC throttle control and 5V power

- AILE - Aileron Y-cable

- ELEV - Elevator servo

- RUDD - Rudder servo

- GEAR - Unused - Can be used for elevator or aileron gyro gain

- AUX1 - Unused - Can be used for full aileron control, e.g. flapperons or spoilerons

Hook-up for 5 channels, full aileron control:

- BAT/Bind - Only used for binding

- THRO - ESC throttle control and 5V power

- AILE - Aileron servo left

- ELEV - Elevator servo

- RUDD - Rudder servo

- GEAR - Unused - Can be used for elevator or aileron gyro gain

- AUX1 - Aileron servo right

A little cool quirk I was surprised by, the ESC beeps are actually coming from the motor. Feeding short pulse burst to the motor dissipates as sound, cool!

ESC

- AOXAN AE-25A Programmable ESC

- On-board BEC 5V 2A supply (two 1A FET transistors in parallel)

- User manual

This is the included speed controller. It originally was a 20A unit but the manufacturer bumped it up the 25A after user reports of excess heat development.

Mount the ESC in a location with some airflow, e.g. in the nose section or the bottom space of the fuselage. It might be necessary to extend the motor silicone wires (18 AWG) or the battery wires (16 AWG).

Configuration can be done by setting throttle to full when powering the ESC, the beep sequences will guide you through the different settings. See the user manual for exact details. Currently the Turnigy programming-card does not work with this 25A version.

To set throttle range, before powering on the ESC set the throttle stick to full and apply power. After two short beeps the range is confirmed, move the stick back down for normal mode.

Settings:

- Air brake: On - Hold propeller still on low throttle

- Battery type: Lipo

- Cut-off type: Straight cut-off' - Low battery handling

- Cut-off voltage: High 3.1V

- Start mode: Normal - Instantly accelerate propeller

- Timing mode: High - Alternate current to magnets faster

- Governor mode: Off - Only applicable for helicopters

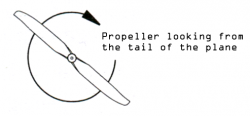

Propeller

For optimal fight performance and efficiency the most suitable propeller seem to be 6x4, e.g. diameter 6-inches and travels 4-inches per rotation. For higher top speed try a 6x5 and better acceleration a 6x3.

The stock 5x5 will work fine, but compared to the 6x4, will run with higher rpm and lower thrust. Try the Webocalc propeller site.

Break away the smaller 4.8 mm adapter ring and sand or cut away the excess plastic tabs. Use medium thick CA glue to fix the ring to the propeller. The ring should be flush against the propeller surface.

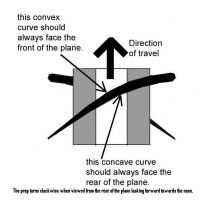

A balanced propeller is essential, use a magnetic bearing propeller-balancer. Either add thin tape to the backside of the lighter blade or sand down the back of the heavier blade. The back is the concaved side, bending inwards.

There are two ways to mount the propeller to the motor.

- Prop-saver - Use a o-ring rubber band around two grub screws

- Collet-adapter - A bushing ring clamped on the motor shaft by a spindle and compression nut

The stock prop-saver is OK but the propeller can vibrate and the o-ring wear out. A properly balanced collet-adapter should be more durable and produce less vibration, thus fly better and quieter.

Mount the propeller with the concaved side facing the tail of the plane. Using the stock, or any other regular propeller, the text should face the toward front of the fuselage.

Center of Gravity

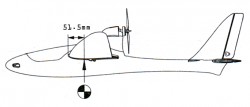

- CG from LE: 51.5mm

An intricate measure for achieving excellent flight characteristics is center of gravity, also called CoG or CG. The CG should be right in the middle of the tube spar cover under the wings. Measured from the leading wing edge it's 51.5 mm back.

The usable CG range seem to go from 49 til 56 mm. Setting CG farther back (up to 56 mm) will put the plane in the sweet spot for minimum drag, the lowest point of induced drag (angle of attack with lowest drag) and parasitic drag (airspeed for lowest drag by moving against air fluid resistance).