MakerBot Replicator 1: Difference between revisions

(Created page with "A few steps to keep the MakerBot running smoothly and continously. == Improvements == * Add blue thread-lock to all grubscrews on all the axis to prevent them to fall out * Use ...") |

(→Setup) |

||

| (44 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

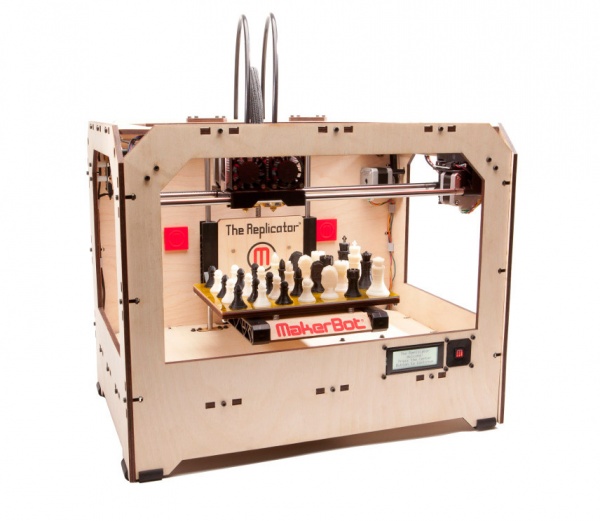

[[Image:MakerBot Replicator 1.jpg|600px|right]] | |||

A few steps to keep the MakerBot running smoothly and continously. | A few steps to keep the MakerBot running smoothly and continously. | ||

== | * [[MakerBot Replicator 1 Firmware Upgrade]] | ||

* Add blue thread-lock to all grubscrews on all the axis to prevent them to fall out | * [[MakerBot Replicator 1 Upgrades and Repairs]] | ||

* Use Triflow | |||

* Replace the system fan with a large 80x80 mm fan to reduce noise | == Specifications == | ||

This is the technical specificatiosn provided when it was first introduced 19. Jan. 2012 [http://www.thingiverse.com/thing:18813]: | |||

* [http://ivc.no/makerbot/makerbot_replicator_user_guide_mt524.pdf MakerBot Replicator 1 User Guide] - PDF | |||

The Replicator is MakerBot's newest and best yet personal 3D printer. With a build envelope that's roughly the size of a loaf of bread, it gives you the power to go big, and with the new MakerBot Stepstruder MK8, built-in Dualstrusion is possible for the first time. | |||

* Build envelope: 225 x 145 x 150 mm or 8.9 x 5.7 x 5.9 inches | |||

* Build Volume: almost 5 liters | |||

* Layer thickness: Choose .2-.3 mm with stock nozzle. | |||

* Stock nozzle diameter: 0.4 mm | |||

* Speed: 40 mm/s | |||

* Flow rate: approximately 24 cc/hr | |||

* Maximum recommended extruder temperature: 230 C | |||

* Maximum temperature for heated build platform: 120 C | |||

* Positioning precision: 2.5 micron on Z axis 11 micron on XY axes | |||

Electronics | |||

* MakerBot MightyBoard single-piece motherboard | |||

* 5 axis, 1/16 micro-stepping motor control | |||

* 4x20 LCD character display and multi-directional control pad | |||

* Piezoelectric buzzer | |||

* Software-controllable RGB LED lighting | |||

* Universal Power Supply - 100-240V, 50/60Hz, 4.0A (input), and takes standard IEC cable | |||

Software | |||

* Controlled through ReplicatorG | |||

* Compatibility: Linux, Windows, and OSX | |||

* Print from SD card or over USB | |||

* Input file type: STL, gcode | |||

Materials | |||

* Works with ABS, PLA, and other materials | |||

* Filament diameter: 1.75 mm | |||

Mechanical | |||

* Linear ball bearings | |||

* Precision ground 8 mm shafts | |||

* Durable ABS injection-molded parts | |||

* Snap-on, snap-off carriage assemblies | |||

* Overall dimensions: 320 x 467 x 381 millimeters or 12.6 x 18.4 x 15 inches | |||

* Shipping weight: 14.5 kg / 32 lbs | |||

== My Setup == | |||

This was a gift for helping the team out with graphics illustrations. | |||

* Model: The Replicator - Dual Extruder | |||

* Ordered: January 2012 | |||

* Delivered: July 2012 | |||

* Serial: 109xx | |||

* Stock firmware: v5.5 (ReplicatorG 037) | |||

* Stock filament: black and natural white (yellow) | |||

Mainboard: | |||

* MakerBot Mightyboard Rev. E | |||

** MCU: ATmega1280-16AU | |||

** Serial/USB: ATmega8U2-MU | |||

** Thermocouple amplifier: MAX6675 | |||

** RGB LED driver: PCA9533 4-bit I2C-bus LED dimmer | |||

Stepper motors: | |||

* Stepper motor X and Y axis: Moons Stepping Motor type 17HD4063-01N 60162810 12/04/05 | |||

** Ball bearing: 2x Bona 625Z per motor | |||

* Driver: MakerBot BotStep17 Rev. E - see the [[MakerBot Replicator Upgrades]] page | |||

** Controller: Allegro A4982 DMOS Microstepping Driver | |||

== Files == | |||

* [http://ivc.no/makerbot/makerbot_replicator_user_guide_mt524.pdf MakerBot Replicator 1 User Guide] - PDF | |||

* [http://beta.ivc.no/makerbot/MakerBot_SD_card_August2012.zip MakerBot SD card August 2012] - zip archive of the included SD card | |||

* [http://beta.ivc.no/makerbot/makerbot_replicator_dual_extruder_v5.5.txt MakerBot Replicator v5.5 machine information] - system information and default print profile | |||

== Setup == | |||

=== Mechanical setup === | |||

The basic setup of the MakerBot replicator is quite simple, below is a compressed version of the [http://www.makerbot.com/docs/replicator/unboxing/ official guide]. | |||

# Open and remove the top large cardboard piece along with the user manual and take the entire Replicator out of the box | |||

# Slide out the large accessories box and open it to take out the extruder and place it on the extruder platform | |||

# Move the build platform up by pulling on both of the inner back supports of the build platform to remove the cardboard piece and the two filament spools | |||

# In the accessories box, find the two black hex screws and fasten the extruder (the washers are for the extruder plunger maintenance) | |||

# Add the rubber feet to the side panels under the bot to dampen the vibrations and increase friction on the MakerBot's working surface | |||

# Refit the heated build platform cable below the platform to the bottom plate, adjust position of the cable to limit slack | |||

# Press the black filament guide tubes onto the extruder holders and clip the guides in place on the back | |||

# Hook the spool supports to the back of the MakerBot, with the top tap going in upwards | |||

# Unpack the filament spools and put them onto the support with the filament pointing from the bottom and up towards the center of the backpanel, cut the bent end using a plier and feed them through the guides till they hit the extruder | |||

# Find, or use the supplied US, power cord and plug it into the adapter and the other end to the four pin socket on the Replicator | |||

# Lastly, flip the power switch to power up the bot and and skip to the next section to perform the software calibration | |||

=== First-time calibration === | |||

The [http://www.makerbot.com/docs/replicator/fre/ first run experience] steps below tunes and sets up the build platform and extruder. | |||

# An automatic setup script will be displayed on the LCD display, press the middle 'M' soft key to continue | |||

# Tighten the thumb screws on the underside of the build platform to make sure the platform does not hit the extruder nozzle/heads | |||

# Adjust the height of the platform by loosening two screws at a time as per the instructions, repeat the calibration one more to fine tune the platform, use the included MakerBot business card and aim for just a hair above, card is 0.12 mm and printer resolution is 0.20 mm | |||

# Heat the extruder and wait for it to hit 220 degrees C | |||

# Unhook the black filament guides from the top of the extruder and load the filaments by feeding it through the stepstruder hole until the extruder motor hook onto it | |||

# A fine string of plastic will start to collect on the build platform, press 'M' when the color is right (some residual ABS might be present) and remove the plastic | |||

# Now, it is time to print a complete model, from the menu pick a model from the included SD card (not any starting with acc_* just yet) | |||

# Congratulations, the preliminary calibration of the Replicator is done! | |||

=== Software setup === | |||

The Replicator can be controlled both from the on-board MakerBot user controls and the ReplicatorG printer software. Models can be loaded via USB or from the SD card. To prepare a SDL model, use ReplicatorG to create the necessary Gcode bot instructions file and the actual .s3g MakerBot processing file. | |||

The steps below can also be found on the [http://www.makerbot.com/docs/replicator/software/ official Replicator software page]. | |||

# Download the latest build of the open source ReplicatorG software, including the drivers for Windows | |||

# Perform the installation and setup Python (2.7.3) if necessary | |||

# From the Machine -> Machine Type (Driver) menu pick Replicator single or dual | |||

# Pick the correct serial port from Machine -> Connection (Serial Port) | |||

# Open the Control Panel to get to know the Jog, LED, temperature, stepper functionality of the bot | |||

# Open a SDL file from the File menu and scale, rotate or move the model to put it flat center on the build platform using the Move buttons | |||

# Hit Generate Gcode and then Build or put the file on an SD card, to print the model! | |||

== Printing settings == | |||

These are my 'go to' printer settings for the Replicator 1: | |||

* Extruder temperature: 235C | |||

* Speeds: | |||

** First layer: 20mm/s | |||

** Floor surface fills: 20mm/s | |||

** Insets/first inner wall: 20mm/s | |||

** Outliners/outer wall: 20mm/s | |||

** Sparse roof surface fills: 45mm/s | |||

* Infill density: 20 to 80% - depending on strength requirement | |||

* Number of shells/walls: 2 to 3 - depending on strength requirement | |||

* Support material extruder: same as model color | |||

* Raft material extruder: same as model color | |||

* Raft margin: 5.0mm | |||

* Support: On when needed | |||

* Extra support: Off | |||

Reset of the settings is just default from the Standard pre-configured settings profile. | |||

== Firmware updates == | |||

Updating the firmware on the Replicator 1 is a bit of a process. Resetting the board and starting the upload (avrdude) process requires exact timing. | |||

* [[MakerBot Replicator 1 Firmware Upgrade]] | |||

There is now also an alternative firmware by Simplify 3D: | |||

* [https://www.simplify3d.com/support/hardware-setup-guides/makerbot/ Simplify 3D Sailfish firmare] | |||

== Maintenance and improvements == | |||

* Add blue thread-lock to all grubscrews on all the axis to prevent them to fall out [http://www.youtube.com/watch?v=v3cnEr1sriQ&feature=plcp] | |||

* Use Triflow or similar PTFE lubricant to all metal-to-metal mechanical motion [http://www.makerbot.com/docs/replicator/maintenance/] | |||

* Replace the system/case fan with a large 80x80 mm fan to reduce noise | |||

* Add a adhesive label on the right side of the joy-pad to indicate the insertion point for the SD card | * Add a adhesive label on the right side of the joy-pad to indicate the insertion point for the SD card | ||

* Remove the ABS residue from the drive gear regularly [http://www.makerbot.com/docs/replicator/maintenance/] | |||

* Fit side and top covers to prevent dust from settling on the extruder and internal components | |||

* Enable accelerated prints to increase the print speed and efficiency, see below | |||

* To avoid warping of the prints, use PVA wood glue diluted in water (1 part glue, 3/4 part glue) and apply a thin film on the build surface 30 seconds before the print begins | |||

== Accelerated prints == | |||

A new feature which appeared on community 3D printers early in 2012 was the ability to accelerated the printing process. What this means is that instead of linearly moving the position by instantaneously starting and stopping the motors, the travel speed is gradually increased and decreased. While this method is slower when using the same travel feedrate as before, it will be faster when increasing, or doubling, the travel feedrate. The bot will not shake and vibrate as violently and work smoothly. But make sure to use high resolution models/gcode. | |||

* [http://www.makerbot.com/docs/software/june2012update/ MakerBot accelerated prints] | |||

== Cutting models == | |||

Sometimes you got a model which is too large for the build platform and need to slice it into smaller pieces. This is easily done using netfabb Basic. | |||

* [http://www.netfabb.com/basic.php netfabb basic] - just click through (skip) all the registration | |||

In the lower right corner, drag the sliders to the specific dimensions and hit execute cut, select each piece and right-click to save as STL (not ASCII). | |||

== Estimate part costs == | |||

To calculate how much it costs to print a part is quite easy since it is built into ReplicatorG [http://www.thingiverse.com/thing:18627] [https://groups.google.com/forum/?fromgroups=#!topic/makerbot/MI8Ck0beFwc]. | |||

# In ReplicatorG, pick Gcode -> Edit Slicing Profiles and edit the main profile | |||

# Select the Analyze menu and then the Analyze menu item | |||

# Pick Statistics tab and then check Activate Statistic and Save Statistics, and enter the values for machine time and material cost | |||

# Now, save all and go back to the main screen, pick GCode and Generate to generate the new gcode for the model | |||

# When the process finishes, a summary will show the time estimate, cost estimate and expected filament mass | |||

Latest revision as of 08:19, 14 June 2017

A few steps to keep the MakerBot running smoothly and continously.

Specifications

This is the technical specificatiosn provided when it was first introduced 19. Jan. 2012 [1]:

The Replicator is MakerBot's newest and best yet personal 3D printer. With a build envelope that's roughly the size of a loaf of bread, it gives you the power to go big, and with the new MakerBot Stepstruder MK8, built-in Dualstrusion is possible for the first time.

- Build envelope: 225 x 145 x 150 mm or 8.9 x 5.7 x 5.9 inches

- Build Volume: almost 5 liters

- Layer thickness: Choose .2-.3 mm with stock nozzle.

- Stock nozzle diameter: 0.4 mm

- Speed: 40 mm/s

- Flow rate: approximately 24 cc/hr

- Maximum recommended extruder temperature: 230 C

- Maximum temperature for heated build platform: 120 C

- Positioning precision: 2.5 micron on Z axis 11 micron on XY axes

Electronics

- MakerBot MightyBoard single-piece motherboard

- 5 axis, 1/16 micro-stepping motor control

- 4x20 LCD character display and multi-directional control pad

- Piezoelectric buzzer

- Software-controllable RGB LED lighting

- Universal Power Supply - 100-240V, 50/60Hz, 4.0A (input), and takes standard IEC cable

Software

- Controlled through ReplicatorG

- Compatibility: Linux, Windows, and OSX

- Print from SD card or over USB

- Input file type: STL, gcode

Materials

- Works with ABS, PLA, and other materials

- Filament diameter: 1.75 mm

Mechanical

- Linear ball bearings

- Precision ground 8 mm shafts

- Durable ABS injection-molded parts

- Snap-on, snap-off carriage assemblies

- Overall dimensions: 320 x 467 x 381 millimeters or 12.6 x 18.4 x 15 inches

- Shipping weight: 14.5 kg / 32 lbs

My Setup

This was a gift for helping the team out with graphics illustrations.

- Model: The Replicator - Dual Extruder

- Ordered: January 2012

- Delivered: July 2012

- Serial: 109xx

- Stock firmware: v5.5 (ReplicatorG 037)

- Stock filament: black and natural white (yellow)

Mainboard:

- MakerBot Mightyboard Rev. E

- MCU: ATmega1280-16AU

- Serial/USB: ATmega8U2-MU

- Thermocouple amplifier: MAX6675

- RGB LED driver: PCA9533 4-bit I2C-bus LED dimmer

Stepper motors:

- Stepper motor X and Y axis: Moons Stepping Motor type 17HD4063-01N 60162810 12/04/05

- Ball bearing: 2x Bona 625Z per motor

- Driver: MakerBot BotStep17 Rev. E - see the MakerBot Replicator Upgrades page

- Controller: Allegro A4982 DMOS Microstepping Driver

Files

- MakerBot Replicator 1 User Guide - PDF

- MakerBot SD card August 2012 - zip archive of the included SD card

- MakerBot Replicator v5.5 machine information - system information and default print profile

Setup

Mechanical setup

The basic setup of the MakerBot replicator is quite simple, below is a compressed version of the official guide.

- Open and remove the top large cardboard piece along with the user manual and take the entire Replicator out of the box

- Slide out the large accessories box and open it to take out the extruder and place it on the extruder platform

- Move the build platform up by pulling on both of the inner back supports of the build platform to remove the cardboard piece and the two filament spools

- In the accessories box, find the two black hex screws and fasten the extruder (the washers are for the extruder plunger maintenance)

- Add the rubber feet to the side panels under the bot to dampen the vibrations and increase friction on the MakerBot's working surface

- Refit the heated build platform cable below the platform to the bottom plate, adjust position of the cable to limit slack

- Press the black filament guide tubes onto the extruder holders and clip the guides in place on the back

- Hook the spool supports to the back of the MakerBot, with the top tap going in upwards

- Unpack the filament spools and put them onto the support with the filament pointing from the bottom and up towards the center of the backpanel, cut the bent end using a plier and feed them through the guides till they hit the extruder

- Find, or use the supplied US, power cord and plug it into the adapter and the other end to the four pin socket on the Replicator

- Lastly, flip the power switch to power up the bot and and skip to the next section to perform the software calibration

First-time calibration

The first run experience steps below tunes and sets up the build platform and extruder.

- An automatic setup script will be displayed on the LCD display, press the middle 'M' soft key to continue

- Tighten the thumb screws on the underside of the build platform to make sure the platform does not hit the extruder nozzle/heads

- Adjust the height of the platform by loosening two screws at a time as per the instructions, repeat the calibration one more to fine tune the platform, use the included MakerBot business card and aim for just a hair above, card is 0.12 mm and printer resolution is 0.20 mm

- Heat the extruder and wait for it to hit 220 degrees C

- Unhook the black filament guides from the top of the extruder and load the filaments by feeding it through the stepstruder hole until the extruder motor hook onto it

- A fine string of plastic will start to collect on the build platform, press 'M' when the color is right (some residual ABS might be present) and remove the plastic

- Now, it is time to print a complete model, from the menu pick a model from the included SD card (not any starting with acc_* just yet)

- Congratulations, the preliminary calibration of the Replicator is done!

Software setup

The Replicator can be controlled both from the on-board MakerBot user controls and the ReplicatorG printer software. Models can be loaded via USB or from the SD card. To prepare a SDL model, use ReplicatorG to create the necessary Gcode bot instructions file and the actual .s3g MakerBot processing file.

The steps below can also be found on the official Replicator software page.

- Download the latest build of the open source ReplicatorG software, including the drivers for Windows

- Perform the installation and setup Python (2.7.3) if necessary

- From the Machine -> Machine Type (Driver) menu pick Replicator single or dual

- Pick the correct serial port from Machine -> Connection (Serial Port)

- Open the Control Panel to get to know the Jog, LED, temperature, stepper functionality of the bot

- Open a SDL file from the File menu and scale, rotate or move the model to put it flat center on the build platform using the Move buttons

- Hit Generate Gcode and then Build or put the file on an SD card, to print the model!

Printing settings

These are my 'go to' printer settings for the Replicator 1:

- Extruder temperature: 235C

- Speeds:

- First layer: 20mm/s

- Floor surface fills: 20mm/s

- Insets/first inner wall: 20mm/s

- Outliners/outer wall: 20mm/s

- Sparse roof surface fills: 45mm/s

- Infill density: 20 to 80% - depending on strength requirement

- Number of shells/walls: 2 to 3 - depending on strength requirement

- Support material extruder: same as model color

- Raft material extruder: same as model color

- Raft margin: 5.0mm

- Support: On when needed

- Extra support: Off

Reset of the settings is just default from the Standard pre-configured settings profile.

Firmware updates

Updating the firmware on the Replicator 1 is a bit of a process. Resetting the board and starting the upload (avrdude) process requires exact timing.

There is now also an alternative firmware by Simplify 3D:

Maintenance and improvements

- Add blue thread-lock to all grubscrews on all the axis to prevent them to fall out [2]

- Use Triflow or similar PTFE lubricant to all metal-to-metal mechanical motion [3]

- Replace the system/case fan with a large 80x80 mm fan to reduce noise

- Add a adhesive label on the right side of the joy-pad to indicate the insertion point for the SD card

- Remove the ABS residue from the drive gear regularly [4]

- Fit side and top covers to prevent dust from settling on the extruder and internal components

- Enable accelerated prints to increase the print speed and efficiency, see below

- To avoid warping of the prints, use PVA wood glue diluted in water (1 part glue, 3/4 part glue) and apply a thin film on the build surface 30 seconds before the print begins

Accelerated prints

A new feature which appeared on community 3D printers early in 2012 was the ability to accelerated the printing process. What this means is that instead of linearly moving the position by instantaneously starting and stopping the motors, the travel speed is gradually increased and decreased. While this method is slower when using the same travel feedrate as before, it will be faster when increasing, or doubling, the travel feedrate. The bot will not shake and vibrate as violently and work smoothly. But make sure to use high resolution models/gcode.

Cutting models

Sometimes you got a model which is too large for the build platform and need to slice it into smaller pieces. This is easily done using netfabb Basic.

- netfabb basic - just click through (skip) all the registration

In the lower right corner, drag the sliders to the specific dimensions and hit execute cut, select each piece and right-click to save as STL (not ASCII).

Estimate part costs

To calculate how much it costs to print a part is quite easy since it is built into ReplicatorG [5] [6].

- In ReplicatorG, pick Gcode -> Edit Slicing Profiles and edit the main profile

- Select the Analyze menu and then the Analyze menu item

- Pick Statistics tab and then check Activate Statistic and Save Statistics, and enter the values for machine time and material cost

- Now, save all and go back to the main screen, pick GCode and Generate to generate the new gcode for the model

- When the process finishes, a summary will show the time estimate, cost estimate and expected filament mass