MakerBot Replicator 1 Adapting A4988 Replacement Driver: Difference between revisions

From ivc wiki

Jump to navigationJump to search

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

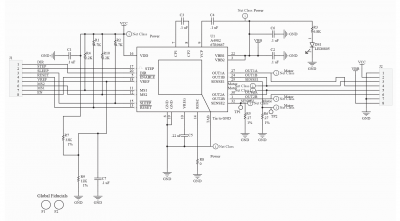

[[Image:MakerBot Replicator BotStep17 schematic.png|400px|right| | [[Image:MakerBot Replicator BotStep17 schematic.png|400px|right|thumb|BotStep17]] | ||

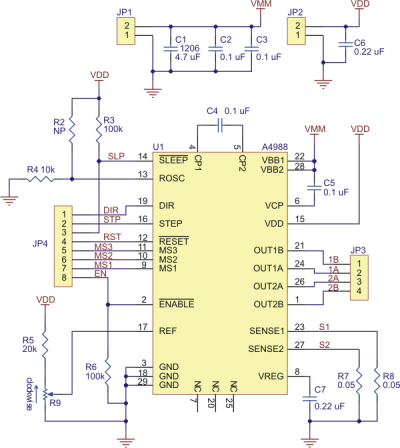

[[Image:MakerBot Replicator Polulu A4988 schematic.png|400px|right| | [[Image:MakerBot Replicator Polulu A4988 schematic.png|400px|right|thumb|Polulu A4988]] | ||

The BotStep17 driver board on the MakerBot Replicator 1 (and 2/2X) uses the A4982 stepper drive IC. It is hard to get replacement driver boards for this model. An popular alternative which is used by many other 3D printers is the A4988. It can be adapted to work with the MakerBot 3D printers. | The BotStep17 driver board on the MakerBot Replicator 1 (and 2/2X) uses the A4982 stepper drive IC. It is hard to get replacement driver boards for this model. An popular alternative which is used by many other 3D printers is the A4988. It can be adapted to work with the MakerBot 3D printers. | ||

Revision as of 11:57, 15 June 2016

The BotStep17 driver board on the MakerBot Replicator 1 (and 2/2X) uses the A4982 stepper drive IC. It is hard to get replacement driver boards for this model. An popular alternative which is used by many other 3D printers is the A4988. It can be adapted to work with the MakerBot 3D printers.

Differences

- A4988 includes 1/8th step resolution, although the MakerBot firmware utilizes 1/16th resulution

- A4982 boards has the Vref pin exposed on the pin headers

- Most A4988 boards has the pin-out flipped-around, so the pins stick out the other way from what the MakerBot is using

- A4982 boards has a better thermal design with exposed copper surface

- All A4988 board set the current limit by turning a trimpot, while A4982 on MakerBot is done digitally

Adapting A4988 boards

Flipping around the pin headers

- Unsolder all the pins from the driver board

- Do this by carefully removing the plastic shoulder and removing the solder using a solder sucker pump

- Clean all the vias and widen them using a small drill bit if necessary

- Prepare two new 8-pin 2.54mm pin header strips

- Remove the MS3-pin on all the headers

- Solder the pin header on with the pins sticking out from the component side, like on the BotStep17

- Use a short piece of wire and solder it between MS3 and VDD pin on the flat surface of the driver board

Adjusting trimpot current limit

- Check what the Rsense resistor value is on the board (or schematic), usually either 0.27/0.2/0.05 Ohms - the MakerBot sets the current limit to 830mA (0.830A)

- Find the Vref you need to calculate the value of the trimpot by solving this equation Vref=(8*Rsense)*0.830, for instance 0.2 Ohm gives (8*0.2)*0.833=1.33V

- Use a multimeter to measure the total resistance of the trimpot between the pads opposite of the third pad

- Calculate the desired resistance to tune for by putting the Rpot value into the equation Radjust=(20+Rpot)*1.33/5, for instance 8.2k gives (20+8.2)*1.33/5=7.5 or 7.5k Ohms to adjust for

- Use the multimeter to measure the resistance between ground and the top of the trimpot, adjust the screw until it matches the calculated value

- Done, insert into the Mightyboard with the DIR and GND pins facing the stepper motor connector