Water Cannon Robot

Lately a friend of mine and I have talked about a new robotic arm project, as a summer activity. The idea is to create a stationary autonomous robot that can detect motion in the immediate vicinity and activate a pump to spray water in the direction of the object.

The project will be based on servos, brackets for mechanics, electric pump, motion and range sensors, video streaming, and java programming/sequencing.

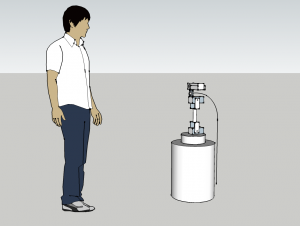

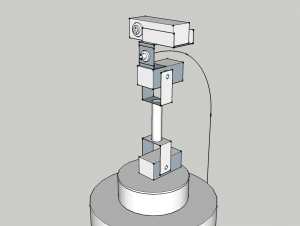

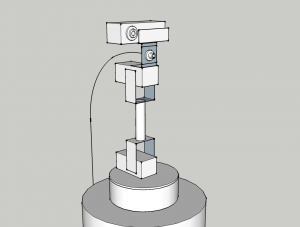

Sketch

This is a sketch drawn in Google Sketch-Up. Took approx. 1.5 hour to get the base done.

Build

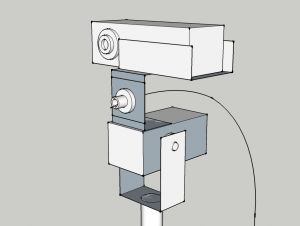

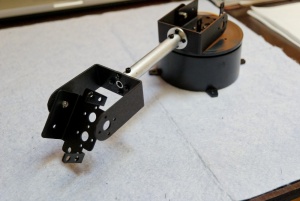

Arm

A company named Lynxmotion is offering an excellent range of parts to build a robotic arm. With all kinds of bracket and connectors, it's possible to build almost everything imaginable. Makes it very flexible to build things.

Box

The box is made out of fiberglass and painted in black. The dimensions were approximations and given to a friend to work out of. It turned out to be quite a good fit and some room to spill.

Outter dimensions: 34.8 x 59.8 x 43.2 cm (WxHxD) Inner dimensions: 32.6 x 57.5 x 41.5-42.0 cm (WxHxD) - Volume: 0,079 m3, 78 Liters

Attaching feet to the box was took some work to figure out as the bottom was not plane and level.

Equipment

The following components has to fit inside the box:

- Pump components:

- Watertank 19L

- Hose 1/2" 12mm 5-8m for compression

- Solenoid Valve 1/" 12mm + 12V leads

- Hose Reduction Valve Kit 1/2" to 1/4"

- Electric and controller components:

- Leadbattery 12V 18Ah

- Eee PC 7" + 12V to 9V adapter

- WRT54GL Wireless Router + 12V leads

- Dual Relay board connected to RFID controller board

- Robot Arm components:

- Phidget RFID Controller Board w/USB cable

- Phidgets Advanced Servo Controller Board w/USB cable + 12V leads

Pump, battery, solenoid valve, brackets mounts

2009-07-26 - The mounts for all the pumping, electrics, and shelving inside the box is done. The aluminum brackets ware leftovers from a stairs repair in the building, dimensions was great for this project.

To avoid noise and vibration from the water pump, which is actually quite silent, I mounted a copper-plate between two rubber membranes. The feet on the pump is rubber and I added 4 rubber rings to the other side of the plate.

As the bottom of the box wasn't plane I used a few washers to lift the brackets to a level plane, especially the battery brackets. The battery bay has a foam matte to level the battery when it's seated.

Remote Control

The final idea includes the ability to remotely control the arm. The Java API for the Phidget servo controller allow for remote calls via IP. The only difference is to use a different "signature" a.k.a number of arguments when calling the servo Open() function, and to specify the IP address and port for main machine where the controller and network service is running.

Live Video Streaming

As for the streaming software, it had to be something with zero buffering, low-delay, and compression overhead. I tried the free Windows Media Encoder and Expression Encoder kits to stream via the MMS protocol, but I couldn't get the buffering/delay below 4 seconds.

Turned out only a more proprietary application/protocol could deliver the real time stream I wanted. Unreal Streaming Technologies develop three components for streaming video; Live Server for each camera, Media Server to aggregate all the incoming streams, and the Media Player to receive the streaming either directly from the Live Server or via the Media Server. Free but with some limitations on number of streams and codecs.

The real time input lag is no more than 300 ms, which is very respectable.

References

- Lynxmotion Picture Gallery - Shows most of their robots

- Lynxmotion Videos - like to stonehedge and chess videos

- Building Lynxmotion BRAT

- Lynxmotion owner finds success with robot kits - Interview at the end

- Modified Lynxmotion J5 build thread

- What sonar system(s) are you using?