T-Rex 250 Setup

This shows the setup of my T-Rex 250 and the experience I've had learning and experimenting with the build. Please visit RC Heli Wiki for an excellent resource regarding helicopter terms and concepts.

Follow this guide to-to-bottom, get a good mechanical setup before setting up the electronics. A great companion is Bob White a.k.a Finless' videos.

Prerequisite

Follow the manual to setup the basic build and then use these steps to do the finer adjustments. The virtue of this setup should be to make the most adjustments as precise as possible. Any sloppy or oblique leveling will have an adverse affect later on.

Blades

Grip

The right amount grip on the blades can be tested by gently hitting the leading edge of the blades with your finger they should fold back about 45 degrees. If they fold all the way back and bind with the blade grip then they're too loose. The blades will swing back and forth in FFF due to airspeed differences between the advancing and retreating blades. This is normal but having a little bit of friction helps to dampen it and make a smoother flight. However you need to make sure both blades blade bolts are tightened the same amount.

Balance

Correct blade balancing and blade weight will reduce vibration and stabilize the helicopter. It's an essential part of the setup. Make sure the surface you're performing the balancing is perfectly level.

A good way to balance the blades consist of a two part method:

- Find the center of mass (or center of gravity) of each blade by applying trim tape to the end of the lighter blade

- Then, use a blade balancer to apply trim tape to center of mass mark on the ligher blade until they're level

The video linked below shows the procedure.

Tracking

Bad tracking is caused by one blade tracking a little higher or lower than the other. By marking each blade with contrasting tape it's possible to see which one need adjustment.

The tracking can be fixed by lengthen or shortening the link holding the main rotor spindle. Only do adjustment by one whole turn at a time. If a half turn is needed, don't turn the link a half a turn but go to the link one step down on the Bell Hiller level arms. These arms will have more range and will give the rotor spindle more gradual control.

Servos

A build tip to avoid having the servo arm hit the main gear on the left side of the T-Rex 250, is to swap the aileron and pitch servos. Then the servo arm on the left side will not have a steep angle against the holes in the main gear. When swapped, the arm will point in the same direction as the main gear rotation. If it hits, it won't get stuck.

The elevator servo should be installed on the inside of the frame, with the main mounts on the inside.

Receiver

AR6100e receiver setup (receiver - device):

- THRO - ESC

- AILE - Right cyclic servo

- ELE - Rear cyclic servo

- RUD - Gyro (3-wires plug)

- GEAR - Gyro (1 wire plug - gain)

- AUX1 - Left cyclic servo

Other receivers wil have different layout.

Radio

Create a new profile for the helicopter and reset all the settings. Make sure there are no sub-trims, revo-mix turned on, 50%/50%/50% swash mix, and other settings different from the default or suitable values. Watch the beginning of Finless CCPM setup to get a good start.

Head

The head setup should mechanically be as symmetrical and zero-pitched as possible. The radio should have a straight throttle curve in normal mode before starting the adjustments.

Install the servos and mount a suitable servo arm 90 degrees to the swashplate. Connect the rods to the swashplate with the length specified in the manual. Note that the following method to change the direction of the servo is only used on the throttle/pitch, for elevator, aileron, and rudder is reversed using swash mixing. Move the throttle stick slightly up and watch the servos, all three should move collectively up to raise the swashplate, if not, go into the radio setup and reverse the direction of the affected servo.

The head is split up in 3 levels (top-to-bottom); Bell-Hiller mixer level, washout arms level, and swashplate level (look at the picture below). On zero-pitch the Bell-Hiller and washout is level. That's determined by the lengths of the link-rods connecting the levels. The washout arms level should be in the middle positioned between minimum and maximum pitch while the arms remain level.

Once they're level, remove the rotor head and use a swashplate leveling tool on top of the swashplate and adjust the length of the pushrods to perfectly level the swashplate. The leveling tool fits on top of the swashplate and will reveal any gaps on either side of the 3 servo-links.

If everything seem level, use a digital caliper verify and duplicate the length of related link rods. This will reduce vibrations and tracking issues even more.

CCPM - Collective Cyclive Pitch Mixing

CCPM Setup:

- 3 servo

- 120° degrees apart

- Swash mix (aileron, elevation, pitch): 40-45% (higher values might cause binding/too great pitch)

- Maximum/Minimum pitch: 10.0° (max. 11.0°)

This is a compact summary of RC Heli Wiki and Bob Finless White videos, please refer to those for details.

The CCPM mixing controls the pitch and movement of the rotor and flybar, thus throttle/pitch (up/down), aileron (left/right), and elevation (forward/backward).

It's called collective because there are 3 servos involved. There are two types of CCPM, mechanical bell crank and electronic mixing. The latter one is used on most helicopters today but requires precision servo setup and some radio configuration. The radio is set-up to mix the 3 servos in order to move the swash plate in the right direction and plane, be it up-down, left-right, or forward-backward.

First check if the servos are going in the right direction, if one servo goes in the oposite direction, reverse that channel. Alternatively, if you move aileron left, but the swashplate moves right, go into the swash mixing, change the positive aileron percentage to negative value to reverse the movement.

Swash mixing controls the pitch of the blades. A pitch gauge is mounted on the main blades and is used to measure the pitch against the flybar. The higher the value, the steeper the pitch. A regular setup usually use collective pitch 10°, or 11° for more flexibility. The maximum and minimum pitch should never bind or lock the servos. Aileron and elevator pitch is normally 6°.

After the links are set up, everything is level, swash mixing done, the movement of just aileron or elevator should not affect the other. This issue is called CCPM interaction and can be handled by watch the flybar pitch at aileron and elevator position, and use travel adjust (not sub-trim) to counter the reaction (see Finless CCPM video 2).

- RC Heli Wiki CCPM Setup

- Bob White CCPM setup videos

- Bob Finless White CCPM 1 video

- Bob Finless White CCPM 2 video

- CCPM interaction

- Jermo's DX7 Setup Video

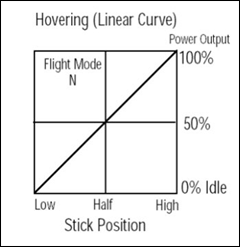

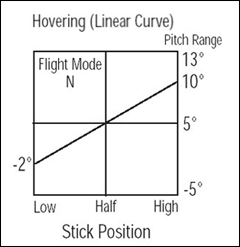

Pitch/Throttle curves

The idea behind pitch and throttle on one stick is to keep a constant headspeed. If the pitch is steep more engine power is required to keep the headspeed revolutions up. This is accomplished by setting up curves on the radio for controlling the pitch and throttle individually. There is usually a 5-point coordinate system to set the percentage at a specific stick position. Many, up to 3, curves can be used for different flight modes, hovering and 3D mode being the primary.

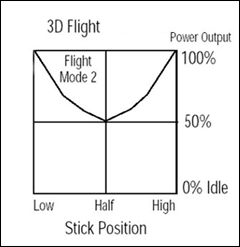

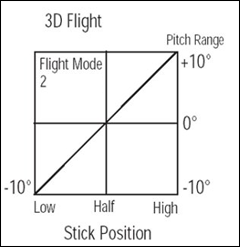

On the radio there's a way to switch between Normal Mode (hovering), Stunt Mode #1 (3D), and Stunt Mode #2 (more power 3D). Stunt mode is also referred to as IdleUp 1 and IdleUp 2, while hovering is called Normal mode. A last mode is Throttle Hold for auto-rotation on engine failure, a second switch is normally used for this.

Normal Mode is used during spin-up and hovering. With the stick down the engine will be off and with 70% up the helicopter should be hovering. These parameters are mainly set-up on the radio by altering the engine throttle and rotor pitch curve.

With Stunt Mode turned on the hovering mode is turned into a flexible mode where the helicopter can be flown up-side-down. Essentially the Normal Mode above 50% is mirrored to the 0-49% section of the stick, but with a negative rotor pitch instead. Look at the picture below to understand the difference between Normal and Stunt.

While setting up the curves, there is an option to enable "Exponential". Expo smoothens the curve and stick input will have a finer feel, not that rough, requires more stick movement to get the right input. But it's not recommended to keep expo on as it removes some of the real feel of the helicopter and can hinder progression.

Normal, hovering mode example (left throttle, right pitch):

Idle Up, 3D stunt mode example (left throttle, right pitch):

The throttle curve dips on the middle because the pitch is close to 0 degrees, thus requiring less power. Higher pitch requires more engine power to keep the head speed constant.

The manual for the helicopter usually specifies suitable pitch and throttle curves.

Dual Rates

Dual Rates, as the name suggests, can be used to setup two different servo ranges to limit the maximum throw, or travel. This lowers the sensitivity and can be used to lower the sensitivity of the helicopter.

If the sensitivity is 80%, full stick input will move the servo arm 80% of the maximum range. Making dual rates useful for new users and hovering.

Tail

Setup:

- 5 mm from servo center

Gyro

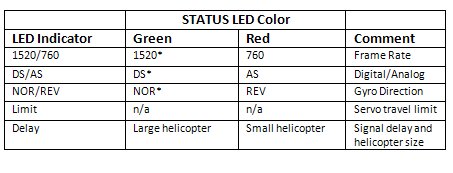

GP750 settings:

- Pulse frame: 1520us

- Servo type: DS (Digital Servo)

- Servo direction: Normal

- Servo travel adjustment: Limit set with no binding

- Heli type/delay: Small heli - Delay: 0

The gyro is a device connected between the receiver and the rudder servo, it will stabilize the tail by counter the torque reaction of the main rotor. There are two types, head hold mode continuously tries to hold the tip of the helicopter at a constant angle, while the other mode, rate mode, dampens any external push to the tail. The former is preferred for normal hovering and acrobatics, while the second is mostly used for scale models.

On the AR6100e receiver the 3 wire plug is connected to the RUD channel and the single gain wire to the GEAR channel. When powering on the receiver and gyro, don't move the heli and or touch the transmitter sticks. A green light will indicate heading hold mode and red rate mode.

Setup

- Gain: 70-75% (20-25% heading hold)

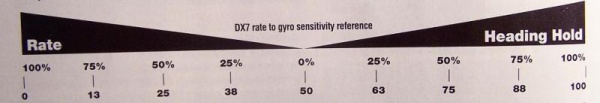

The gyro is connected to the receiver by two plugs. One for the rudder input and one for gain. Gyro gain is used to control how much the gyro tries to control the tail and measured in percentages. The range 0-49% is called rate mode (also called normal mode) and the tail will not automatically bounce back to the original position if it has been pushed by an external force, but rather dampen the movement. While the upper 51-100% range is called heading hold mode (also referred to as AHTCS) and will try to keep the front of the helicopter at a constant angle/heading.

The intermittent range (0-49% and 51-100%) is then used to fine tune the tail. If the tail wags back and forth the gain amount is reduced and if the heading isn't holding (pirouetting) the gain is increased.

Note that the gain wire is electronically connected like any regular servo and if the channel is reversed so will the rates. The gear channel is normally connected to a physical switch on the radio and this switch can be used to change the gyro mode (heading or rate).

There are two ways to set gyro gain, either via the gyro menu or set the channel end points, a.k.a maximum/minimum travel range or adjustment. The former is preferred.

To find the true gyro gain use these equations:

- When using end points/travel adjustment: (End point value) / 1.44

- Or when using the (preferred) gyro sens menu: (Gyro value in radio - 50) * 1.44

A good default start value is around 32% gyro gain (72% in radio gyro mode).

Guides:

- RC Heli Wiki Controlling Gyro Gain

- Need Help Setting up 401 on a Spektrum AR6100 and DX6i

- Bob Finless White Gyro 101

ESC

The default configuration:

- Soft start

- 6v BEC to receiver/servos

Although the ESC is pre-programmed from factory, re-program it to make sure the throttle range matches the transmitter stick range. It also fixes any issues that might be introduced during manufacturing or storage.

Higher BEC voltage will give the servos more torque and reaction time.

Battery

What makes a good battery pack good is the ability to hold voltage under load. When you start to fly aggresively, some battery pack will drop more voltage than other, resulting in bogging of head speed. A good battery pack will have minimal voltage drop during heavy load, resulting in more punch and consistent speed.

Deans Connector

There are two main types of battery connectors, Deans and JST. Bullet plugs are used between the motor and speed controller. The JST connector is known have a low amperage rating (10-15A) and after awhile the surface will oxidize, eventually resulting in more resistance and heat. It could in extreme cases cause flight problems or unexpected twitching during peak load (e.g. full throttle and pitch).

Replacing the plug with Deans connectors will improve the contact surface area and thus rating (50-75A). They're also easier to connect and disconnect, compared to JST.

Charging

Always use a quality charger when dealing with LiPo batteries. The batteries carry a lot of energy and requires special attention.

A normal LiPo battery for helis run in series of 2 or 3 cells. Combining cells in series means higher voltage and greater discharge capacity. To charge a LiPo battery, a balancing charger is recommended to properly charge each cell individually. Similarly charging only via the main leads will cause the capacity be unevenly distributed across the cells and could cause damage to the battery, and in extreme cases dangerous situations.

The continuous discharge capacity of a battery is specified in 'C's, where 1C is equal the capacity of the battery, e.g. a TP 910 mAh 11.1v 20C LiPo battery can handle a continuous discharge of 20C * 860 mA, 17200 mA or 17.2 A. Some batteries also specify the peak, or burst, discharge capacity, e.g 40C, but this is only for short periods of time.

When charging a LiPo, most batteries can only be charged at 1C or less, e.g 910 mAh, or 0.9 A and lower. Some batteries can also be fast charged but only when specified in the manual/label. The voltage can be calculated by multiplying 3.7V by the number of cells, e.g. 2 series 7.4V or 3 series 11.1V. Some chargers can detect if the wrong voltage/series is picked.

If the voltage of any individual cell is under 3.3V, the battery is considered dead and should not be attempted to be charged.