Water Cannon Robot

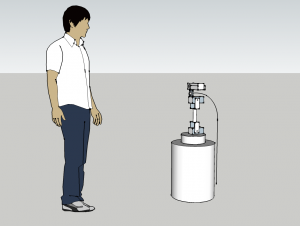

Lately a friend of mine and I have talked about a new robotic arm project, as a summer project. The idea was to create a stationary autonomous robot that can detect motion in the immediate vicinity and activate a pump to spray water in the direction of the subject.

Lately a friend of mine and I have talked about a new robotic arm project, as a summer project. The idea was to create a stationary autonomous robot that can detect motion in the immediate vicinity and activate a pump to spray water in the direction of the subject.

The project is based on servos, brackets for mechanics, electric pump, motion and range sensors, video streaming, and java programming/sequencing.

Sketch

This is a sketch drawn in Google Sketch-Up. Took approx. 1.5 hour to get the base done.

Build

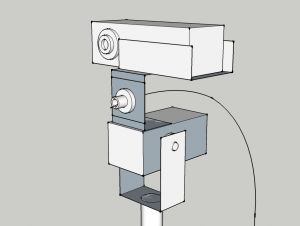

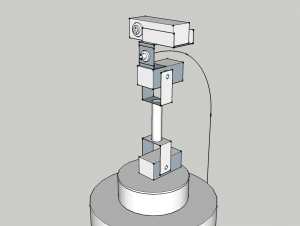

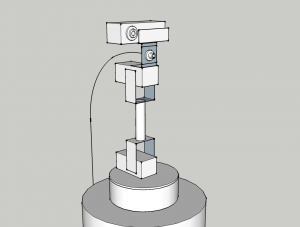

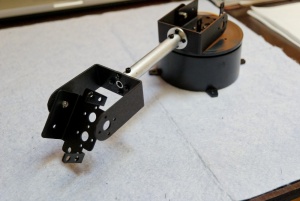

Arm

A company named Lynxmotion is offering an excellent range of parts to build a robotic arm. With all kinds of bracket and connectors, it's possible to build almost everything imaginable. Makes it very flexible to build things.

Box

The box is made out of fiberglass and painted in black. The dimensions were approximations and given to a friend to work out of. It turned out to be quite a good fit and some room to spill.

Outter dimensions: 34.8 x 59.8 x 43.2 cm (WxHxD) Inner dimensions: 32.6 x 57.5 x 41.5-42.0 cm (WxHxD) - Volume: 0,079 m3, 78 Liters

Attaching feet to the box was took some work to figure out as the bottom was not plane and level.

Equipment

The following components had to fit inside the box:

- Water pump components:

- Water pressurepump 12V, 6A power, 12L/min, 35psi/2.4bar

- Watertank 19L - the watercooler kind

- Hose 1/2" 12mm 5m - for building compression

- Solenoid Valve 1/" 12mm + 12V leads

- Hose Reduction Valve Kit 1/2" to 1/4"

- Hose 1/4" 6 mm 1m - leading up to the arm

- Parts from paint spray gun - to focus water beam

- Electronics and controller components:

- Lead-acid battery 12V 18Ah

- Eee PC 7-inch computer + 12V to 9V power adapter

- WRT54GL Wireless Router + 12V leads

- Dual Relay board connected to RFID controller board

- Enclosure box with 8 switches + LED indicator

- Robot Arm components:

- Phidget RFID Controller Board w/USB cable

- Phidgets Advanced Servo Controller Board w/USB cable + 12V leads

- 3x Hitec HS-322HD Standard Servos

Pump, battery, solenoid valve, brackets mounts

2009-07-26 - The mounts for all the pumping, battery, and shelving inside the box is done. The aluminum brackets ware leftovers from a stairs repair in the building, dimensions was great for this project.

To avoid noise and vibration from the water pump, which is actually quite silent, I mounted a copper-plate between two rubber membranes. The feet on the pump is rubber and I added 4 rubber rings to the other side of the plate.

As the bottom of the box wasn't plane I used a few washers to lift the brackets to a level plane, especially the battery brackets. The battery bay has a foam matte to level the battery when it's seated.

The water pumps is rated to provide 2.4 bar pressure. To even out the pressure, and to avoid having a expansion tank, I used 5 meter 1/2" water hose packed together to build up pressure and hopefully when the valve is released the pump can keep up. The valve is a simple 12V solenoid valve made out of plastic. It's closed by default and open when current is applied.

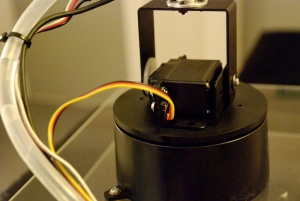

Arm mount

2009-07-31 - For the robot arm to look like it belongs on top of the rather large box, I decided to lift up a little by adding a 5 cm spacer made of two plexiglass sheets. It's put together by four screws and short pieces of 12 mm pipe holding the sheets apart. Nuts are pressing on the opposite side. Holes on top of the box makes it possible to install and fasten it. To make the surface on the top sheet smooth, the screw holes have been drilled out in an inverted cone shape.

A fifth hole is used to feed to control cables and water hose. A guide pipe made of plastic is just long enough to rest on top of the box between the sheets. The diameter of the hole in the plexiglass sheets are 20 mm and 16 mm on the box, this allows the cables to route through but not the guide pipe. There's enough space to allow one 9 mm hose, usb cable, and several servo wires.

This setup makes it feel clean and I think it looks pretty cool too.

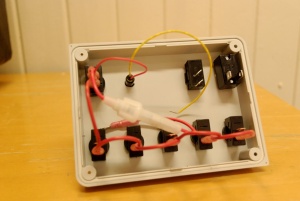

Wiring

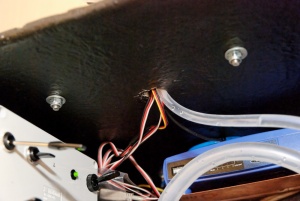

2009-08-08 - To control the power to all the devices in the box, each device has its own switch to turn on/off power. The pump and battery also has a fuse. All the wiring and switches go into a junction box on the left side of the box. The front of the box can fit 10 switches, but here only 8 is needed plus 1 for power LED. They're split into; five for controlling power, two for override, and one for main power from battery.

Connecting everything and making sure to keep straight was (obvious) bothersome, especially with the additional override wiring. I used regular 1.5mm2 wiring (15 AWG) and crimp terminals. Red for positive and blue for negative.

The switches on the lower row are rated for 15A 12V, the main power switch on the top right corner 20A 12V, and the override switches 15A/16A 12V. The switch with the long arm is for the solenoid valve, it's a momentary switch and turns off once released. The rest are regular on/off switches.

To protect the pump a 10A fuse is connected in-line and to protect the battery a 30A fuse (the one inside the jbox) is placed on the positive side of the battery.

Finishing the wiring and connecting the wires to the switches took some time and it's was a relief to see the power LED turn green! I routed the wires through the respective hole for each device.

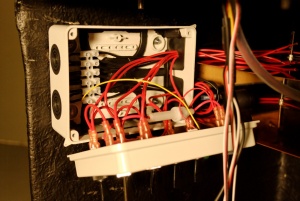

The relay board has 2 Single Pole Double Throw (SPDT) units and is used to control the pump (on/off) and the solenoid valve (trigger/firing). All the servos from the arm are connected to the black advanced servo controller, in addition is the power for the relay switch drawn from one of the servo outputs. Lastly, the temporary RFID board conveniently include two digital outputs, perfect to control the relays (true/false). The RFID part of the board is not used in this project.

The override allow for manual control over the pump and valve if the relay controller is disconnected or not used. Both relays default to Normally Open (NO) configuration.

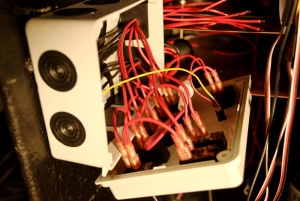

Final

2009-08-14 - The final step of the build will connect together all the major components; main battery power, Eee Pc to servo controller and webcam, and the router for wireless communication with the Eee via ethernet.

When installing the tank, it barely touches the end if the switches and the lower copper sheet (but it fits just nicely). This shows the setup with the power turned off.

Powering on the system is a matter of flipping the switches up (European style) one at a time. The top right switch is main power, and the lower row right to left; router, Eee, servo arm controller, pump, and solenoid vale. The last two on the upper row is used for override, left to right; solenoid valve/trigger momentary-switch, and pump power on switch.

All the servo arm wires, webcam cable, and water hose is feed through the hole on the back-end of the box. Strips are used to keep the wire somewhat tidy.

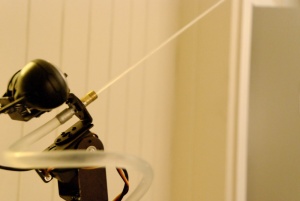

To form the final water beam, a part of an air paint-gun is shortened to proper length and two small holes soldered to keep the water from pressing through the treads. A few extra centimeters of the hose is added to avoid kinks and bends from damaging the hose when the arm is flexing to extremes.

On the absolute top is the arm is the webcam. It's mounted using a pairs of strips tied together. The camera has auto-focus and 2 Megapixel resolution.

A few more pictures of the inside of the box where all the electronics are mounted.

Webcam

The webcam is in fact quite amazing. It can stream 30 fps in 640x480 resolution, meaning it's hardware accelerated. This makes it a perfect fit for Unreal Media Server. The server can capture the raw webcam video stream and forward it without re-encoding it, leaving the Eee to perform more important tasks.

Using the Wifi router a live stream can be send from the webcam to a computer running the Unreal Media Player (proprietary codec). The cool thing is that it's virtually real-time streaming (300-500 ms delay).

Testing

Only a few test runs had to be performed to iron out a few issues. Mainly the programming of the arm and stopping a couple of leaks at the beam-end.

(Yes, the test is performed in-doors, please don't tell anyone!!)

Performance:

- Spray distance: 7-8 meters

- Pump water pressure: 2.4 bar / 35 psi

- Battery capacity: approx. an hour continuous run

- Wifi distance: over 100 meters line of sight

- Tank capacity: 18.9 litre

Programming

Application

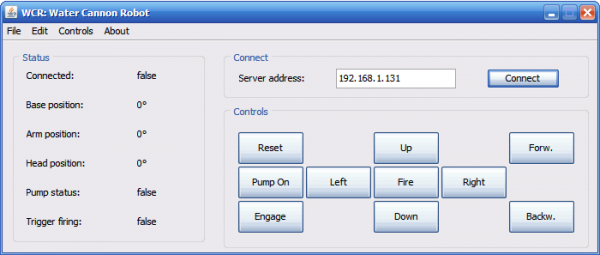

I wrote a new Java application based on some code I had used previously for a Room Control project. In addition to the regular Java libraries, I used the Phidgets API to talk to the relay and control the servo controller. The password is set to 'passwdtochange' in model.class and port 5001 in controller.class.

The app is built and compiled in the Eclipse SDK.

- Download binary/jar - 2010-06-22

- Download source code - 2010-06-22

- Requires:

- Phidget driver: Windows - Mac OS X

- JAR libraries: phidget21.jar - swing-layout.jar

Remote Control

The final idea includes the ability to remotely control the arm. The Java API for the Phidget servo controller allow for remote calls via IP. The only difference is to use a different "signature" a.k.a number of arguments when calling the servo Open() function, and to specify the IP address and port for main machine where the controller and network service is running.

One of the cool things about the API is that it accepts connections from multiple sources, a.k.a. two users can control the robot arm, i.e. one controls the movement of the arm and the other triggers the firing button.

Live Video Streaming

As for the streaming software, it had to be something with zero buffering, low-delay, and compression overhead. I tried the free Windows Media Encoder and Expression Encoder kits to stream via the MMS protocol, but I couldn't get the buffering/delay below 4 seconds.

Turned out only a more proprietary application/protocol could deliver the real time stream I wanted. Unreal Streaming Technologies develop three components for streaming video; Live Server for each camera, Media Server to aggregate all the incoming streams, and the Media Player to receive the streaming either directly from the Live Server or via the Media Server. Free but with some limitations on number of streams and codecs.

The real time input lag is no more than 300 ms, which is very respectable. The delay is slightly more over a local network, but not much.

References

- Lynxmotion Picture Gallery - Shows most of their robots

- Lynxmotion Videos - like to stonehedge and chess videos

- Building Lynxmotion BRAT

- Lynxmotion owner finds success with robot kits - Interview at the end

- Modified Lynxmotion J5 build thread

- What sonar system(s) are you using?

- David Cook Robot Room

- Charging the lead-acid battery